Introduction to Drive Roller:

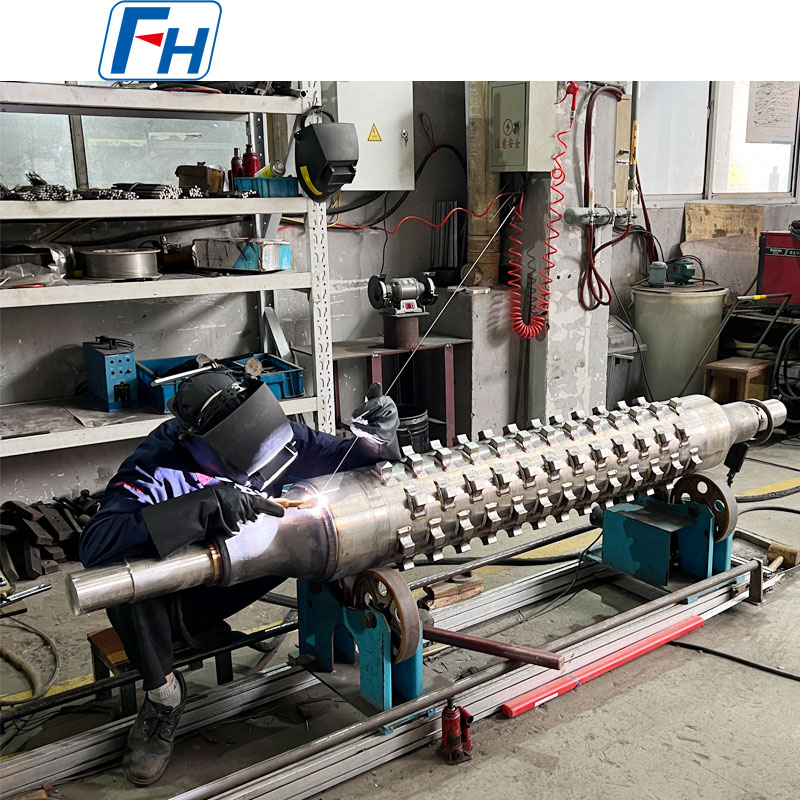

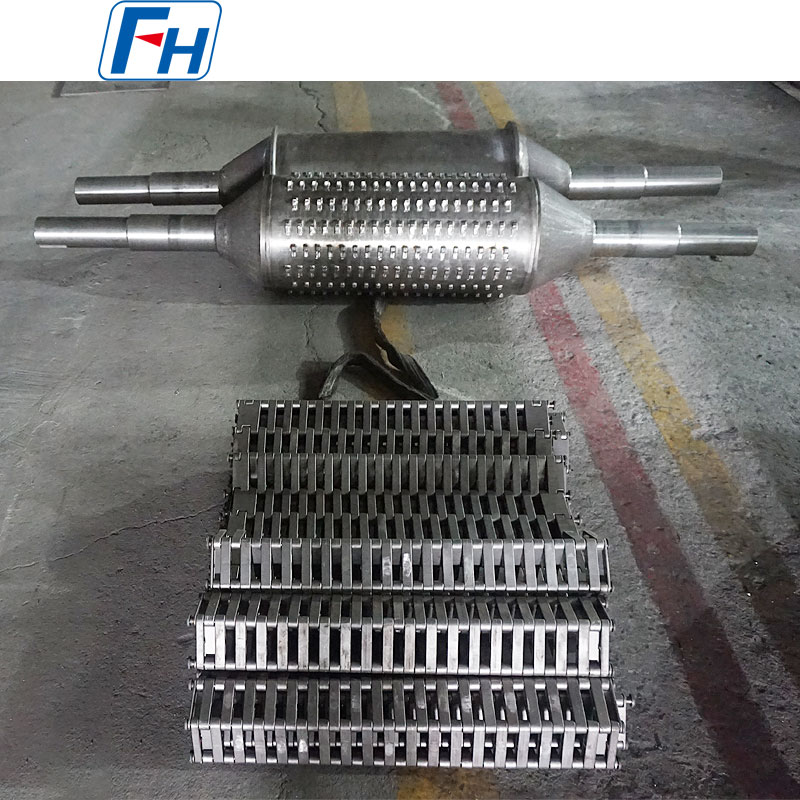

The drive roller is the core power component of conveying/transmission systems, which drives the operation of belts or materials by outputting torque and serves as a key part ensuring stable equipment operation.

Core Definition and Positioning:

Also known as the driving roller, the drive roller is directly connected to power devices such as motors and reducers, converting electrical energy into mechanical energy and outputting torque. As the source of system power, it drives subsequent components to operate through friction with conveyor belts or transmission belts, determining the speed, direction and precision of conveying/transmission.

Structure and Key Configurations:

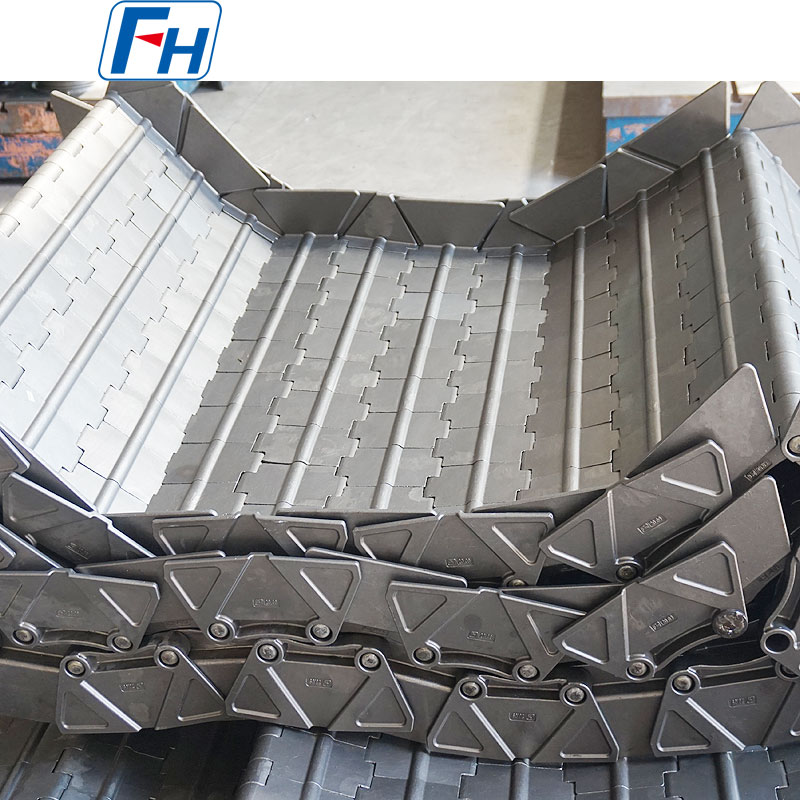

● Main Structure: Composed of a roller body, shaft heads, bearings and seals. Some models are equipped with couplings for connecting power devices.

● Roller Body Design: The roller body is mostly made of materials such as steel, aluminum alloy or heat-resistant stainless steel (e.g., 1.4825). Its outer layer is often covered with wear-resistant materials like rubber or polyurethane to enhance friction and prevent slipping.

● Power Connection: Supports direct motor connection, chain transmission, belt transmission and other methods to meet different power output requirements.

Core Performance Parameters:

● Diameter: Common range is 100-800mm, selected based on load capacity and conveying speed.

● Rotational Speed: Suitable for conveying speeds of 0.1-5m/s, adjustable via reducers.

● Load Capacity: Ranges from light load (several kilograms) to heavy load (tens of tons), corresponding to different industrial scenarios.

● Temperature Resistance: Normal-temperature models are applicable for -20-80℃, while high-temperature models (e.g., 1.4825 material) can withstand 800-1000℃.

Applicable Industries and Scenarios:

● General Industry: Logistics conveyor belts and automated production lines for continuous material transmission.

● Heavy Industry: Mining, metallurgy and building materials industries for conveying heavy-load materials such as ore and cement clinker.

● Special Industries: Printing, dyeing and papermaking industries for driving substrates to operate with high precision; chemical industry for adapting to high-temperature and mild corrosion working conditions.

Key Selection Points:

● Match Power Parameters: Determine the drive roller diameter and transmission ratio according to motor power and rotational speed.

● Adapt to Working Conditions: Select corresponding materials and sealing structures for normal-temperature, high-temperature and corrosive environments respectively.

● Comply with Belt Type: Match the width and thickness of conveyor belts or transmission belts to ensure contact area and friction force.

| 1.4825 Material and Mechanical Properties Table | ||||||||

| Chemical Composition(%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Fe |

| 0.15 - 0.35 | 0.50- 2.50 | ≤2.00 | ≤0.04 | ≤0.03 | 17.00 - 19.00 | 8.00 - 10.00 | ≤0.50 | Bal. |

| Brinell Hardness (HB) | Elastic Modulus | Elongation at Break | Fatigue Strength | Poisson's Ratio | Shear Modulus | Tensile Strength | Yield Strength | Density |

| 150 | 200 GPa | 17% | 160 MPa | 0.28 | 77 GPa | 510 MPa | 260 MPa | 7.7 g/cm³ |

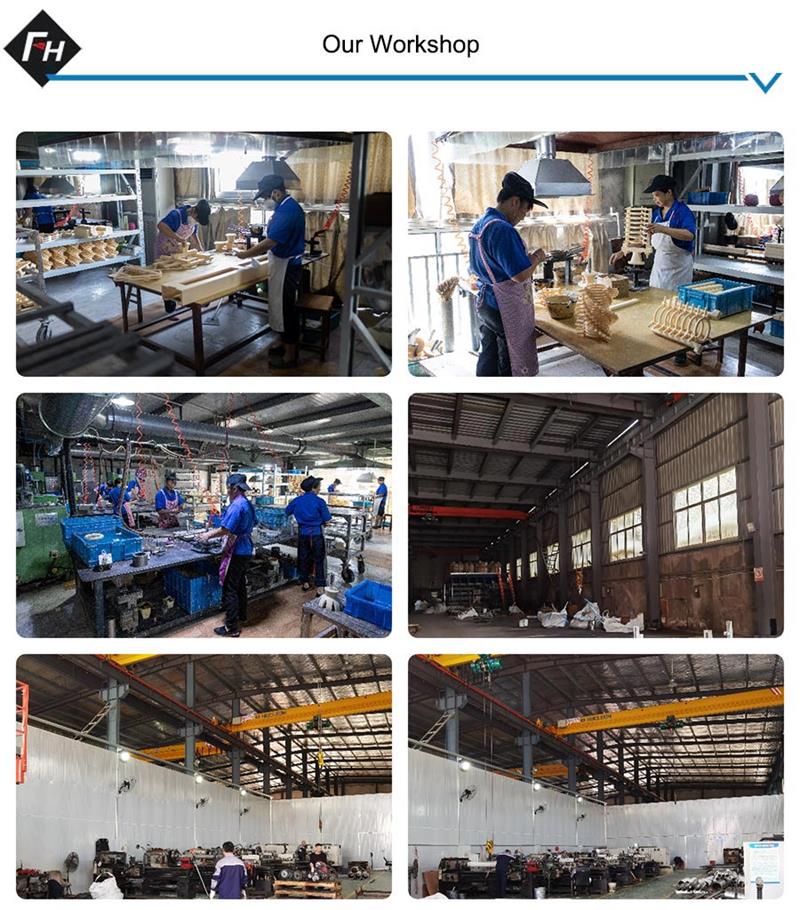

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0086-510-88331288

Tel: 0086-510-88331288  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.