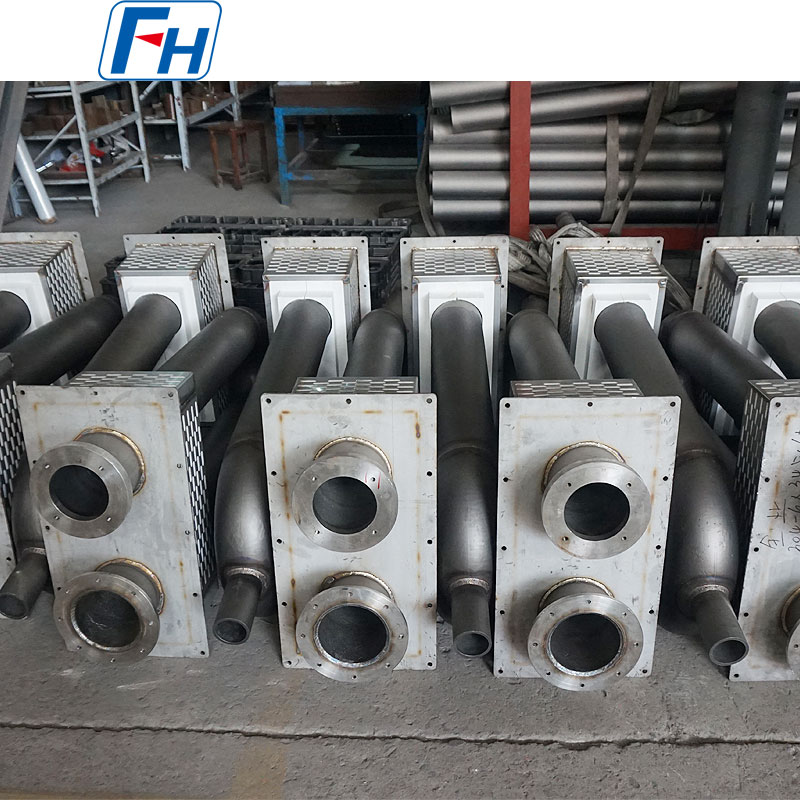

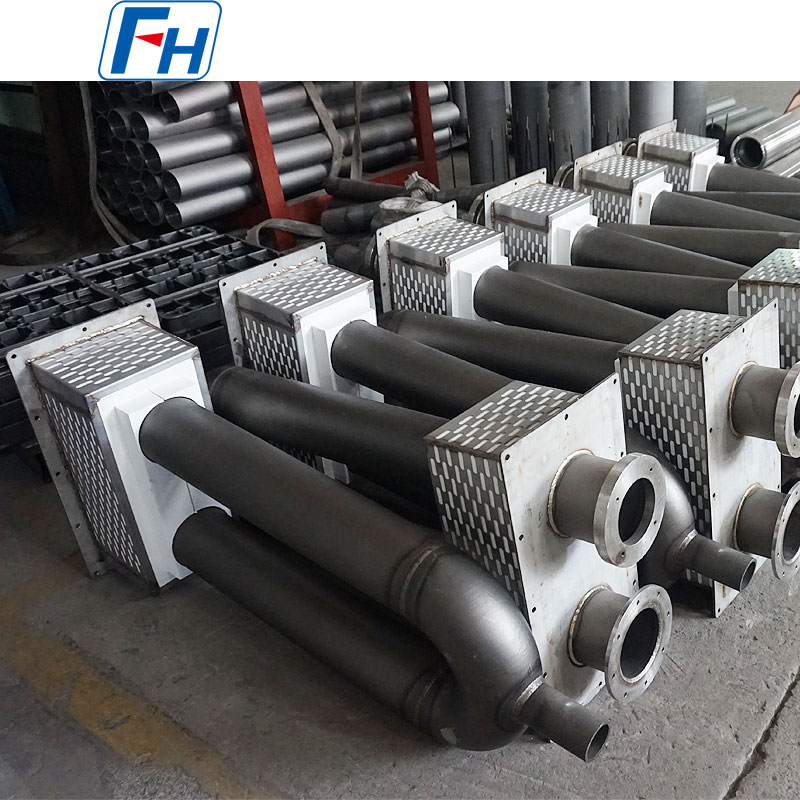

Radiant Tube:

Radiant tubes are indirect heating elements with a core structure consisting of a "heating source + sealed protective sheath." By enclosing the heating source (such as an electric heating element or gas combustion system) within a high-temperature and corrosion-resistant protective sheath, heat generated by electricity or combustion does not come into direct contact with the heated object/medium. Instead, heat is transferred primarily through radiation, supplemented by a small amount of convection, to the furnace lining, workpiece, or space to be heated.

The design aims to prevent direct contact between the heating source and the corrosive and reducing atmosphere within the furnace, minimizing wear and tear on the heating element while ensuring uniform and controllable temperature distribution. They are widely used in industrial applications such as heat treatment (such as carburizing, quenching, and annealing), metal heating, and drying and curing. They are particularly well-suited for furnaces with stringent requirements for environmental cleanliness and atmosphere stability, such as continuous strip heat treatment furnaces, pit-type furnaces, and roller-hearth furnaces.

Radiant tubes are available in different forms, 'U' tube, 'W' tube,single linear tubes, double linear tubes, continuous tube systems, etc., in a wide range of outputs, each to suit particular applications.

Types: W-Type Radiant Tube; U-type Radiant Tube, I-type Radiant Tube and Electrical Radiant Tube

Size: OD50 to OD1500mm

Material Grade: High nickel and high chrome heat resistant alloys, like HU, HT, HK, HP, HW, 24/24NbTiZr,50Cr/50Ni (2.4813), 1.4865, 1.4849, 1.4848, 1.4410, 1.4059, 1.4841, 1.4845, 1.4852, 2.4879 or as per customers’ requirements.

Melting Methods: Electric Arc Furnaces, Induction Furnaces & Vacuum Furnaces

Production Process: Centrifugal Cast Process, Investment Cast Process, Welding Process.

Quality Control: UT,MT,RT,PT,Chemical Analysis Report, Mechanical Property Test,etc.

Heat Treatment Process: Normalizing,Quenching,Tempering,Annealing.

Surface Treatment: shot blasting,painting,plating,polishing,black oxide,transparent anti-rust oil.

Inspection: in-house inspection, third party inspection.

Standards: ANSI,ASTM,ASME,API,JIS,DIN,BS,EN,KS,UNI,SABS,GOST.

Certificates:

1. Chemical Analysis Report

2. Heat-treatment Sheet Report

3. Dimension Size Report

4. DP Test Report

Packing: Seaworthy plywood package on stell pallets or as customer's request Competitive Advantage: Quality control and management for the whole production process, including ingot smelting,casting, heat treatment, machining and strictly final inspection prior to delivery.

Application: Our radiant tube heaters are widely used in heat treatment equipment, auto parts, iron and steel manufacturing,electric power, thermal-mechanical processing,aluminum industry, metallurgical equipment, petrochemical equipment,glass machinery, ceramic machinery,food machinery, pharmaceutical machinery, power engineering industry, and residential appliances.

Material Grade:

| Heat-resistant Steel | |||||||||||||

| / | GB (中) | DIN (德) | ASTM (美) | JIS (日) | Chemical Composition (%) | Maximum operation temperature | |||||||

| C | Si | Mn | Cr | Ni | Nb/Cb | Mo | Other | ||||||

| 1 | ZG40Cr27Ni4 | 1.4823 | HD | SCH11 | 0.30 - 0.50 | ≤2.00 | ≤1.00 | 24.00 - 28.00 | 4.00 - 6.00 | - | ≤0.50 | 1050℃ | |

| 2 | ZG40Cr22Ni10 | 1.4826 | HF | SCH12 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 19.00 - 23.00 | 8.00 - 12.00 | - | ≤0.50 | 950℃ | |

| 3 | ZG30Cr28Ni10 | HE | SCH17 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 8.00 - 11.00 | - | - | 1050℃ | ||

| 4 | ZG40Cr25Ni12 | 1.4837 | HH | SCH13 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 27.00 | 11.00 - 14.00 | - | ≤0.50 | 1050℃ | |

| 5 | ZG30Cr28Ni16 | HI | SCH18 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 14.00 - 18.00 | - | - | 1100℃ | ||

| 6 | ZG40Cr25Ni20Si2 | 1.4848 | HK | SCH21 | 0.30 - 0.50 | ≤1.75 | ≤1.50 | 19.00 - 22.00 | - | ≤0.50 | 1100℃ | ||

| 7 | ZG30Cr20Ni25 | HN | SCH19 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 19.00 - 23.00 | 23.00 - 27.00 | - | - | 1100℃ | ||

| 8 | ZG40Cr19Ni39 | 1.4865 | HU | SCH20 | 0.35 - 0.75 | ≤2.50 | ≤2.00 | 17.00 - 21.00 | 37.00 - 41.00 | - | - | 1020℃ | |

| 9 | ZG40Cr15Ni35 | 1.4806 | HT | SCH15 | 0.35 - 0.70 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 33.00 - 37.00 | - | ≤0.50 | 1000℃ | |

| 10 | ZG40Cr25Ni35Nb | 1.4852 | HPCb | SCH24Nb | 0.30 - 0.50 | ≤2.00 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | 0.8 - 1.8 | ≤0.50 | 1100℃ | |

| 11 | ZG40Cr19Ni39Nb | 1.4849 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 18.00 - 21.00 | 36.00 - 39.00 | 1.2 - 1.8 | ≤0.50 | 1100℃ | |||

| 12 | ZG40Cr24Ni24Nb | 1.4855 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 23.00 - 25.00 | 23.00 - 25.00 | 0.8 - 1.8 | ≤0.50 | 1050℃ | |||

| 13 | ZG40Cr25Ni35 | 1.4857 | HP | SCH24 | 0.35 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | ≤0.50 | 1100℃ | ||

| 14 | ZG1Cr20Ni32Nb | 1.4859 | 0.06 - 0.15 | 0.50 - 1.50 | ≤2.00 | 19.00 - 21.00 | 31.00 - 33.00 | 0.5 - 1.5 | ≤0.50 | 1050℃ | |||

| 15 | ZG45Cr12Ni60 | HW | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 10.00 - 14.00 | 58.00 - 62.00 | 1100℃ | |||||

| 16 | ZG45Cr18Ni66 | HX | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 64.00 - 68.00 | 1100℃ | |||||

| 17 | ZG1Cr28Co50 | 2.4778 | 0.05 - 0.25 | 0.50 - 1.00 | ≤1.50 | 27.00 - 30.00 | ≤1.00 | ≤0.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ | ||

| 18 | ZG30Cr28Co50Nb | 2.4779 | 0.25 - 0.35 | 0.50 - 1.50 | 0.50 - 1.50 | 27.00 - 29.00 | - | 1.50 - 2.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ | ||

| 19 | ZG40Cr28Ni48W5 | 2.4879 | SCH42 | 0.35 - 0.55 | 1.00 - 2.00 | ≤1.50 | 27.00 - 30.00 | 47.00 - 50.00 | - | ≤0.50 | W:4.0 - 5.5 | 1200℃ | |

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0086-510-88331288

Tel: 0086-510-88331288  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.