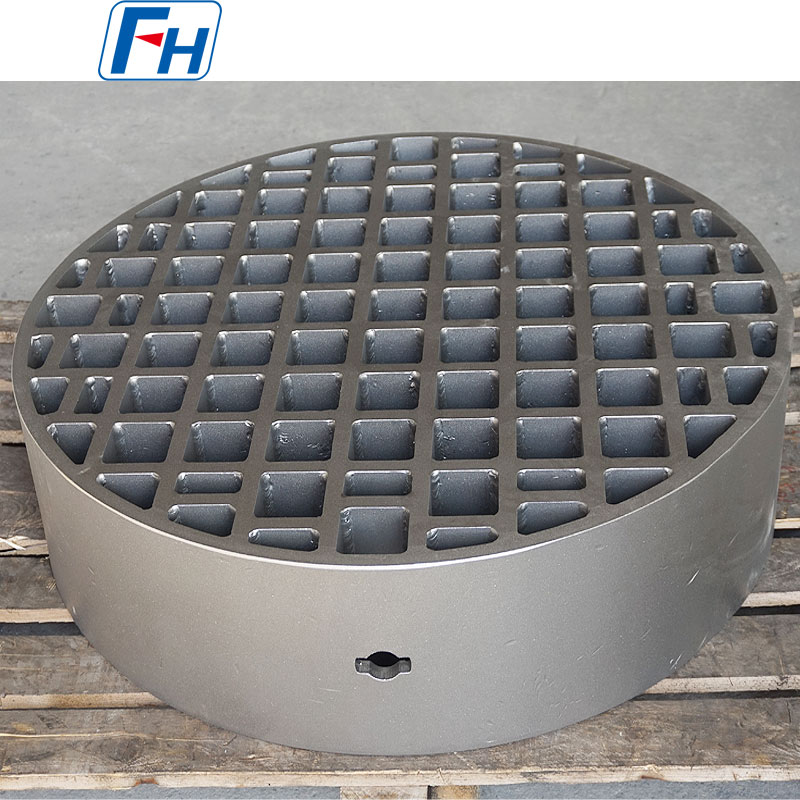

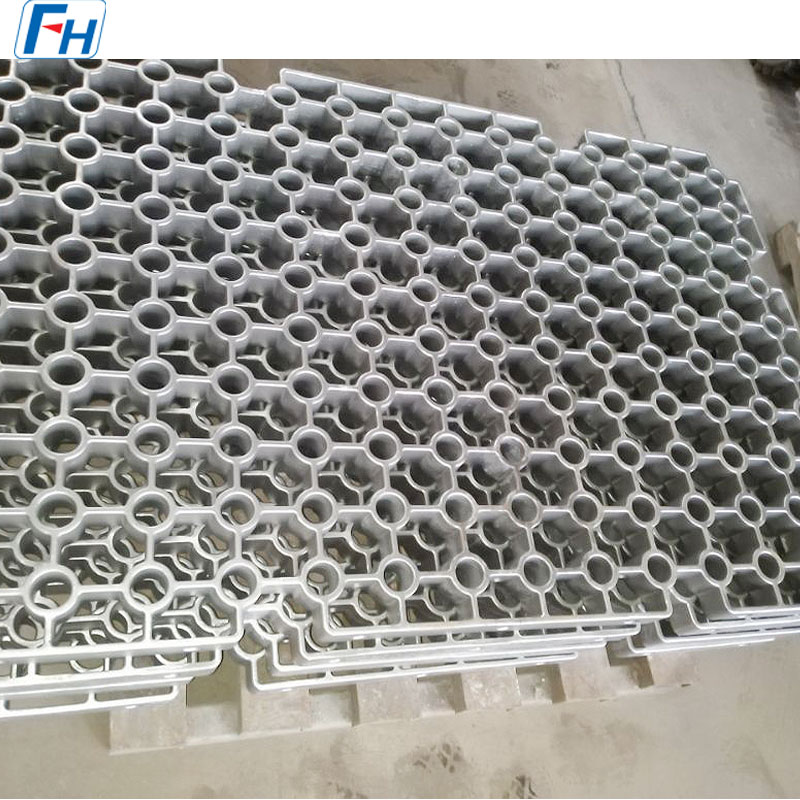

Stellite cobalt-based alloy impellers are impeller components manufactured using Stellite cobalt-based alloys. They possess excellent high-temperature resistance, wear resistance, and corrosion resistance, and are widely used in extreme operating conditions such as aerospace, energy, chemical, and oil and gas industries.

Material Properties:

Stellite cobalt-based alloys use cobalt as a matrix, with the addition of elements such as chromium, tungsten, and carbon. The resulting hard carbide phase allows it to maintain high strength and structural stability in high-temperature (above 1000℃), high-pressure, and corrosive environments, while also exhibiting excellent resistance to abrasive wear, erosion, and adhesive wear.

Applications:

Aerospace: Used in impeller assemblies for jet engines and turbochargers, ensuring reliable operation in high-speed, high-temperature environments and guaranteeing power output.

Energy Industry:

Used as a key impeller component in gas turbines and steam turbines to achieve efficient energy conversion; also used in pump impellers in oil extraction equipment to resist wear and corrosion in harsh downhole environments.

Chemical and Marine Engineering:

Impellers suitable for chemical reactors and seawater desalination equipment, capable of withstanding corrosion from acidic and alkaline media and seawater, ensuring long-term stable operation.

Manufacturing Process:

Typically employs precision casting (such as lost-wax casting), powder metallurgy, or additive manufacturing (3D printing) to ensure the accuracy and performance consistency of complex impeller structures. Some impellers also undergo surface polishing and laser cladding to further enhance wear resistance and sealing performance.

Material Grade Table:

| Stellite 1 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Other | Hardness | Density | Melting Range | ||

| Bal. | 28.00-32.00 | 11.00-13.00 | 2.00-3.00 | Ni, Fe, Si, Mn, Mo | 50-58 HRC 550-720 HV |

8.69 g/cm3 0.314 lb/in3 |

1248-1290ºC 2278-2355ºF |

||

| Stellite 3 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Other | Hardness | Density | Melting Range | ||

| Bal. | 30.50 | 12.50 | 2.30 | Ni, Fe, Si | 48-63 HRC | 8.69 g/cm3 0.314 lb/in3 |

1250-1290°C 2280-2355°F |

||

| Stellite 4 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Other | Hardness | Density | Melting Range | ||

| Bal. | 30.00 | 14.00 | 1.00 | Ni, Fe, Si, Mn | 45-49 HRC | 8.61 g/cm³ 0.311 lb/in³ |

1340–1395ºC 2245–2545ºF |

||

| Stellite 6 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Other | Hardness | Density | Melting Range | ||

| Bal. | 27.00-32.00 | 3.00-6.00 | 0.90-1.40 | Ni, Fe, Si, Mn, Mo | 36-45 HRC 380-490 HV |

8.44 g/cm³ 0.305 lb/in³ |

1250-1360ºC 2282-2480ºF |

||

| Stellite 12 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Other | Hardness | Density | Melting Range | ||

| Bal. | 27.00-32.00 | 7.50-9.50 | 1.40-2.00 | Ni, Fe, Si, Mn | 45-51 HRC 435-590 HV |

8.53 g/cm³ 0.308 lb/in³ |

1225-1280ºC 2240-2335ºF |

||

| Stellite 13 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Ni | Other | Hardness | Density | Melting Range | |

| Bal. | 28.00 | 20.00 | 0.90 | 5.00 | V, Fe, Si, Mn | 45–50HRC | 9.02 g/cm³ 0.326 lb/in³ |

1230–1300ºC 2246-2372ºF |

|

| Stellite 19 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Si | Other | Hardness | Density | Melting Range | |

| Bal. | 31.00 | 10.50 | 1.90 | 1.00 | Ni, Fe | 51-53 HRC | 8.36 g/cm3 0.302 lb/in3 |

1239-1299°C 2263-2370°F |

|

| Stellite 20 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Si | Other | Hardness | Density | Melting Range | |

| Bal. | 32.50 | 17.50 | 2.50 | <2.00 | Mo, Fe, Si | 53-62 HRC | 8.77 g/cm3 0.317 lb/in3 |

1263-1301°C 2305-2374°F |

|

| Stellite 21 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | Mo | C | Si | Other | Hardness | Density | Melting Range | |

| Bal. | 26.00-29.00 | 4.50-6.00 | <0.35 | <3.00 | Fe, Si, Mn | 27-40 HRC 290-430 HV |

8.33 g/cm³ 0.301 lb/in³ |

1295-1435ºC 2360-2615ºF |

|

| Stellite 25 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Other | Hardness | Density | Melting Range | ||

| Bal. | 20.00 | 15.00 | 0.10 | Ni, Fe, Si,Mo, Mn | 20-45 HRC | 8.31 g/cm3 0.300 lb/in3 |

1329-1410°C 2425-2573°F |

||

| Stellite 31 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Ni | Other | Hardness | Density | Melting Range | |

| Bal. | 26.00 | 7.50 | 0.50 | 10.50 | Mo, Fe, Si | 25-35 HRC | 8.61 g/cm3 0.311 lb/in3 |

1340-1395°C 2245-2545°F |

|

| Stellite 190 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Fe | Other | Hardness | Density | Melting Range | |

| Bal. | 27.00 | 14.00 | 3.30 | <3.00 | Ni, Si, Mo, Mn | 52-60 HRC 570-760 HV |

8.66 g/cm³ 0.313 lb/in³ |

1200-1335ºC 2192-2435ºF |

|

| Stellite 250 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | Si | C | Fe | Other | Hardness | Density | Melting Range | |

| Bal. | 28.00 | 1.00 | 0.10 | 20.00 | Mn | 18-29 HRC | 8.05 g/cm3 0.291 lb/in3 |

1380-1395°C 2515-2540°F |

|

| Stellite 694 Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Ni | Other | Hardness | Density | Melting Range | |

| Bal. | 28.50 | 19.50 | 0.90 | 5.00 | V, Fe, Si, Mn | 44-50HRC | 9.02 g/cm3 0.326 lb/in3 |

1237-1296°C 2259-2365°F |

|

| Stellite Star J Alloy | |||||||||

| Nominal Composition (Mass %) and Physical Properties | |||||||||

| Co | Cr | W | C | Ni | Fe | Other | Hardness | Density | Melting Range |

| Bal. | 32.50 | 17.50 | 2.50 | 2.00 | 2.00 | Mn, Si | 50-63 HRC | 8.76 g/cm3 0.316 lb/in3 |

1215-1299°C 2220-2370°F |

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.