Material Characteristics:

Monel K500 is a nickel-based alloy, primarily composed of nickel (63-70%) and copper (27-33%), with added elements such as aluminum and titanium. This combination gives Monel K500 excellent corrosion resistance, high-temperature resistance, and superior mechanical strength. It exhibits strong resistance to seawater, acidic solutions, and various chemical environments, and through age hardening treatment, its strength and hardness are significantly improved compared to ordinary Monel 400.

Specifications:

Monel K500 flanges are available in various sizes according to standards such as ANSI/ASME B16.5, B 16.47 series A&B, B16.48, and BS4504, ranging from 1/2"NB to 60"NB. Pressure ratings are available in 150#, 300#, 600#, 900#, 1500#, and 2500#, and can also be designated as PN6, PN10, PN16, etc., depending on different standards. Flange face types include flat face (FF), raised face (RF), and ring joint (RTJ).

Manufacturing Standards:

Monel K500 flanges are typically manufactured according to ASTM B564, which specifies the requirements for nickel alloy forged fittings, flanges, and valves. They also comply with standards such as ASME B16.5, which specifies flange dimensions, tolerances, material requirements, markings, and pressure-temperature ratings.

Performance Advantages:

Excellent corrosion resistance, maintaining stable performance even in contact with seawater and chemicals; high strength and wear resistance ensure stable operation in high-pressure, high-impact pipeline systems; it also possesses good high-temperature resistance, maintaining its mechanical properties at high temperatures, enabling it to withstand high-temperature operating environments such as oil and gas extraction, operating at temperatures up to 593℃ without losing its mechanical properties and corrosion resistance.

Applications:

In marine engineering, its excellent seawater corrosion resistance makes it widely used in pipeline systems for shipbuilding and offshore oil and gas extraction; in the chemical industry, it effectively resists the erosion of acids, alkalis, and other chemicals, used for connecting pipelines and equipment handling corrosive media; in the aerospace field, its high-temperature resistance and fatigue resistance make it suitable for use in aircraft engines and high-temperature, high-pressure turbine systems.

Appearance and Connection Methods:

Monel K500 flanges typically have a silver-white metallic luster and a smooth surface. Various connection methods are available, commonly including welding (such as socket welding and butt welding) and threaded connections, which can be selected according to the specific application scenario and pipeline system requirements.

| Grade | 200,201,400,K500,625,C276,etc. |

| Standard | ASTM B564, ASME SB564 |

| Dimensions | ANSI / ASME B16.5, B16.47 Series A & B, B.16.48, BS4504, BS10, DIN, EN-1092, MSS SP44 |

| Size | 1/2" - 48" (15NB - 1201NB) |

| Class / Pressure Rating | 150 Class, 300 Class, 201 Class, 900 Class, 1500 Class, 2500 Class, PN6, PN10, PN16, PN25, PN40, PN64, etc. |

| Form | Slip on Flanges (SORF), Threaded Flanges, Weld neck Flanges (WNRF), Blind Flanges, Socket weld Flanges, Lap Joint Flanges, Ring Type Joint Flanges, Spectacle Blind Flanges, Spacer Ring Flanges, Long weld Neck Flanges, Nipo Flange, Nipolet Flanges, Plate Flanges, Flat Flange, Orifice Flanges, Forged Flanges |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint(RTJ) |

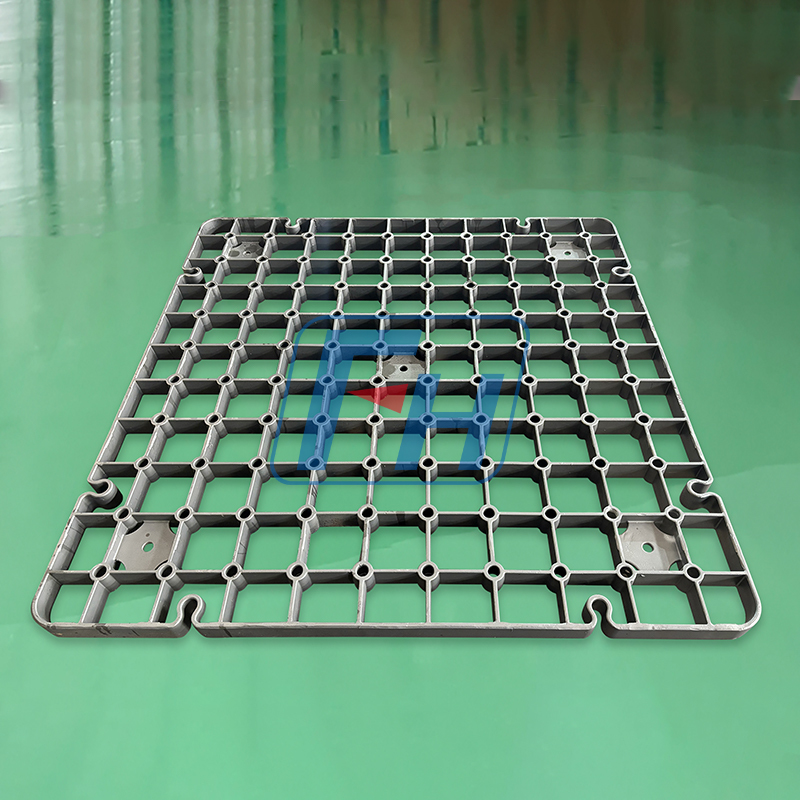

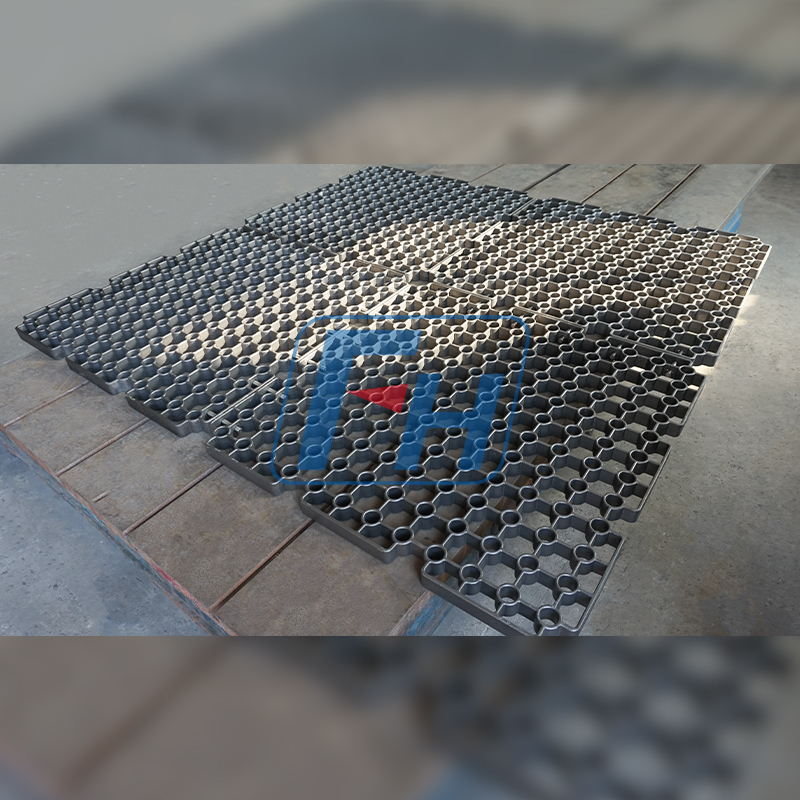

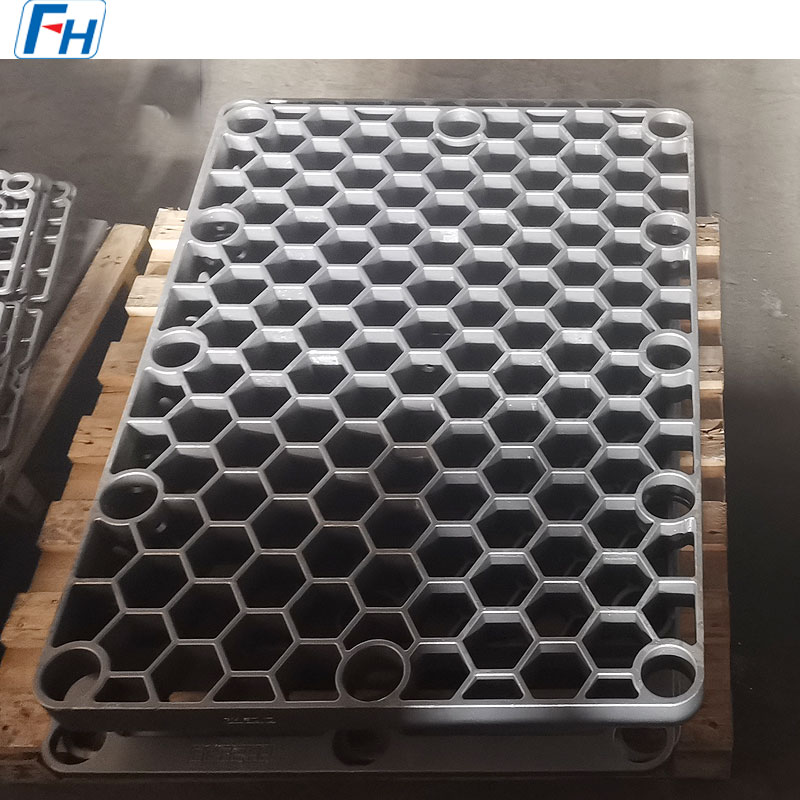

Real Photos of Monel K500 Flanges:

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.