0086-13338774804

0086-13338774804

Get in Touch

Nov 12, 2025

Nov 12, 2025 Content

| Item | Content | Explanation |

| Definition | Cast components that retain dimensional accuracy and structural integrity under severe wear, impact, and corrosion conditions. | Produced from high‑chromium cast iron, alloy steel or special wear‑resistant alloys; hardness, toughness and corrosion resistance are balanced through precision casting, heat treatment and surface‑strengthening. |

| Key Characteristics | High Hardness & Wear Resistance | Alloying elements such as Cr, Mo, Ni raise surface hardness, forming a hard wear layer that dramatically reduces wear rate. |

| Good Impact Toughness | While maintaining hardness, the internal microstructure retains sufficient toughness to resist crack propagation caused by impact loads. | |

| Excellent Corrosion Resistance | Alloy design enables the material to stay intact in high‑temperature, acidic, alkaline or saline‑mist environments, extending service life. | |

| Customizable Design | Dimensions, shapes and internal reinforcement structures can be tailored to the specific requirements of heat‑treatment equipment (furnaces, rollers, fans, etc.). | |

| Common Materials | High‑chromium cast iron, alloy steel, special wear‑resistant alloys | Material is selected according to service conditions to achieve the optimal balance of hardness, toughness and corrosion resistance. |

| Typical Processes | Precision casting, carburizing/nitriding heat treatment, quench‑tempering, laser cladding, etc. | These processes increase the hardness and bonding strength of the wear‑resistant layer. |

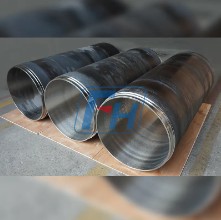

| Application Fields | Furnace supports, rollers, fan blades, heat‑treatment fixtures, wear plates, etc. | Widely used in metallurgy, heat treatment, mining, chemical industry and other high‑wear sectors. |

Wear resistant castings are castings that maintain dimensional accuracy and structural integrity under harsh conditions such as high wear, impact, and corrosion. They are typically made of high-chromium cast iron, alloy steel, or special wear-resistant alloys, and achieve a balance of hardness, toughness, and corrosion resistance through precision casting, heat treatment, and surface strengthening processes.

1.1 High Hardness and High Wear Resistance: The surface hardness of the material is increased by alloying elements (such as Cr, Mo, Ni), allowing it to form a hard, wear-resistant layer during friction.

1.2 Good Impact Toughness: While maintaining hardness, the material retains a certain degree of internal toughness, capable of resisting crack propagation caused by impact loads.

1.3 Excellent Corrosion Resistance: Alloying design maintains surface integrity in high-temperature, acidic, alkaline, or salt spray environments, extending service life.

1.4 Customizable Design: Custom designs for size, shape, and internal reinforcement structures are available based on the structural requirements of different heat treatment equipment (such as furnaces, roller conveyors, and fans).

2.1 Specialized Production Experience: Focusing on the design and manufacturing of alloy steel parts since 2006, accumulating over 15 years of experience in wear-resistant casting R&D.

2.2 Complete Supply Chain: Possessing its own casting workshop, heat treatment facilities, and surface strengthening (laser cladding) technology, enabling one-stop service from raw material procurement to finished product delivery.

2.3 Dual OEM and Wholesale Capabilities: Capable of providing OEM customization for large projects, as well as rapid supply in a wholesale model, meeting the needs of customers of different sizes.

1. Wear Failure

Adhesive Wear: Under high temperature and pressure, metal surfaces adhere to each other and then detach, leading to localized material peeling.

Abrasive Wear: Hard particles impact the casting surface during relative motion, forming pits or scratches.

Impact Wear: High-frequency impacts cause surface micro-cracks, which then expand into macroscopic notches.

2. Thermal Fatigue Cracks

Due to localized temperature gradients caused by thermal cycling, thermal stress accumulates over time, forming fine cracks within the casting and eventually leading to fracture.

3. Corrosion Failure

In working environments containing chlorine, sulfur, or acidic media, alloying elements are corroded, forming corrosion pits and weakening structural strength.

4. Stress Corrosion Cracking (SCC)

Under the combined action of tensile stress and corrosive media, cracks appear at the microscopic level in the material, commonly found in the support components of high-temperature furnaces.

5. Protective Measures of Wuxi Junteng Fanghu Alloy Casting Co., Ltd.

High-Precision Heat Treatment: Carburizing and nitriding processes enhance surface hardness, significantly reducing adhesion and abrasive wear.

Laser Cladding Technology: A layer of high-hardness alloy powder is applied to critical wear-prone areas, forming a self-healing wear-resistant layer to resist impact and thermal fatigue.

Materials Selection Optimization: A variety of material combinations, such as high-chromium cast iron, alloy steel, or duplex steel, are provided for different working conditions to achieve the optimal balance between wear resistance and corrosion resistance.

| Comparison Item | High‑Chromium Cast Iron | Alloy Steel | Remarks / Services from Wuxi Junteng Fanghu Alloy Casting Co., Ltd. |

| Chemical Composition & Microstructure | Contains Cr ≥ 12 %, forming abundant hard Cr‑rich carbides (e.g., Cr₇C₃); matrix is martensite or bainite; hardness 55‑65 HRC. | Strengthened by alloying elements (Cr, Mo, Ni, V, etc.) in solid solution or fine carbides; hardness range 30‑60 HRC, adjustable by heat treatment. | Material‑selection consulting – based on operating conditions we provide a comparative report to help customers choose the most suitable material. |

| Wear Resistance Mechanism | Hard carbides act as “abrasive particles” during sliding, creating a self‑polishing wear layer; ideal for high‑impact, heavy‑load abrasive wear. | Hardening layers formed by carburizing, nitriding or laser cladding; combine high hardness with good toughness, suitable for mixed impact‑abrasive and thermal‑fatigue environments. | Tailored heat‑treatment – carburizing, nitriding, quench‑tempering, etc., to achieve the optimal hardness‑toughness balance. |

| Impact Toughness | Relatively brittle; prone to cracking under strong impact or rapid temperature changes. | More compact internal structure; impact toughness markedly superior to high‑chromium cast iron. | Surface‑strengthening solutions – laser cladding on critical zones of cast iron to raise impact toughness and extend service life. |

| Machinability & Cost | Very hard, difficult to machine; higher post‑processing cost, but raw‑material cost is lower. | After heat treatment it can be machined easily; higher material cost due to alloying elements, but greater flexibility. | Cost optimisation – we propose the most cost‑effective material and processing plan according to order volume and delivery schedule. |

| Typical Applications | Furnace supports, rollers, wear plates, heavy‑load rollers, etc., where abrasive wear dominates. | Heat‑treatment fixtures, radiant tubes, fan blades, furnace rails, components that need both impact resistance and fatigue resistance. | End‑to‑end service – from material selection, heat treatment, laser cladding to final inspection, delivering a complete Wear Resistant Castings solution. |

High-chromium cast iron and alloy steel are two commonly used wear-resistant materials, each with its own emphasis in chemical composition, microstructure, and performance.

1. Chemical Composition and Microstructure

High-chromium cast iron: Contains ≥12% Cr, forming a large amount of hard Cr-enriched carbides (such as Cr₇C₃). The matrix is martensite or bainite, and the hardness can reach 55-65 HRC.

Alloy steel: Strengthened by alloying elements (Cr, Mo, Ni, V, etc.) in solid solution or fine carbides, it has a wider hardness range (30-60 HRC) and can be adjusted through heat treatment.

2. Wear Resistance Mechanism

High-chromium cast iron: The hard carbides act as "abrasives" during the wear process, forming a self-grinding wear layer, suitable for high-impact, heavy-load abrasive wear environments.

Alloy steel: A hardened layer is formed through carburizing, nitriding, or laser cladding, resulting in a combination of high hardness and good toughness, making it suitable for applications involving both impact wear and thermal fatigue.

3. Impact Toughness

High-chromium cast iron has relatively high brittleness and is prone to cracking under strong impact or rapid temperature changes.

Alloy steel, while maintaining hardness, has a denser internal structure, resulting in significantly better impact toughness than high-chromium cast iron.

4. Machining and Cost

High-chromium cast iron has high hardness and is difficult to cut, leading to higher post-machining costs, but its raw material costs are relatively low.

Alloy steel can be machined after heat treatment, offering greater flexibility, but the addition of alloying elements slightly increases material costs.

5. Material Selection Services from Wuxi Junteng Fanghu Alloy Casting Co., Ltd.

Needs Assessment: Providing professional material comparison reports based on the client's operating conditions (temperature, load, wear type).

Customized Heat Treatment: Carburizing, nitriding, or quenching and tempering of alloy steel to achieve the optimal balance between hardness and toughness.

Surface Strengthening Solution: Laser cladding is applied to key areas of high-chromium cast iron to improve impact toughness and extend service life.

Heat treatment and laser cladding are two core technologies for improving the performance of wear resistant castings. They can be used individually or combined to form a composite strengthening system.

1. Heat Treatment Processes

Carburizing: Heating in a carbon-rich atmosphere allows carbon atoms to penetrate the surface layer, forming a high-hardness carburized layer (HRC 55-62), improving wear resistance while maintaining internal toughness.

Nitriding: Nitrogen or ammonia gas is used to penetrate the surface layer at relatively low temperatures, forming a hard nitride layer with a hardness of HRC 60-65, significantly improving corrosion resistance.

Quenching-Tempering: Rapid cooling of alloy steel forms martensite, followed by tempering to reduce internal stress and improve impact toughness.

2. Laser Cladding Technology

Process Principle: A high-power laser melts metal powder or wire and deposits it onto the substrate surface, forming a dense alloy layer. Commonly used cladding materials include Co-Cr, Ni-Mo, and Fe-Cr-C series.

Advantages: The cladding layer forms a metallurgical bond with the substrate, achieving a hardness of HRC 65-70, and the layer thickness is adjustable (0.5-5mm), making it suitable for areas with high localized wear.

Cooling Control: By adjusting the laser power, scanning speed, and preheating temperature, the microstructure can be controlled, preventing crack formation.

3. Process Combination

Carburizing before Cladding: Carburizing is first performed on the overall surface to increase the substrate hardness, followed by laser cladding in critical wear-prone areas, forming a double-layered reinforced structure.

Post-Heat Treatment: Low-temperature tempering is performed after cladding to eliminate residual stress and improve overall toughness.

Experimental testing is a crucial step in verifying the quality of wear resistant castings. Common testing items include wear rate, hardness, impact toughness, and related microstructure analysis.

1. Wear Rate Test

Standard Method: The test uses ASTM G99 (abrasive wear) or ASTM G133 (adhesive wear). The specimen is placed relative to a standard abrasive or opposing material under a set load, rotation speed, and time, and the mass loss is measured.

Calculation Formula: Wear Rate = Δm / (F × L) (Unit: g/N·m), where Δm is the mass loss, F is the normal force, and L is the relative sliding distance.

Result Evaluation: Compare with the benchmark value of similar materials; the lower the value, the better the wear resistance.

2.Hardness Test

Rockwell Hardness (HRC): The surface layer is indented using a Rockwell hardness tester (C scale), and the hardness value is read directly.

Vickers Hardness (HV): Indentation is performed on a microhardness tester with a small load (e.g., 200g). Suitable for measuring the hardness distribution of thin cladding layers.

3. Hardness Distribution: The depth and uniformity of the heat-treated or cladding layer are evaluated through hardness gradient testing (measuring layer by layer from the surface inwards).

4. Impact Toughness Testing

Charpy Impact Test: The specimen is impacted using a standard Charpy impact testing machine (V-notch) at room temperature or high temperature, and the absorbed energy (J) is recorded.

Temperature Effect: For castings operating in high-temperature environments, impact tests are conducted at the corresponding operating temperature (e.g., 400°C) to evaluate high-temperature toughness.

5. Microstructure and Surface Analysis

Metallurgical Microscopy: The microstructure (distribution of martensite, cementite, and carbides) of the carburized, nitrided, or cladding layer is observed.

Scanning Electron Microscopy (SEM) + EDS: The composition and size of the surface hard phases are analyzed to verify the uniformity of the cladding layer.

X-ray Diffraction (XRD): The phase composition is detected to confirm the formation of the desired hard carbides or nitrides.