0086-13338774804

0086-13338774804

Get in Touch

Sep 30, 2025

Sep 30, 2025

1. Uniform heat distribution

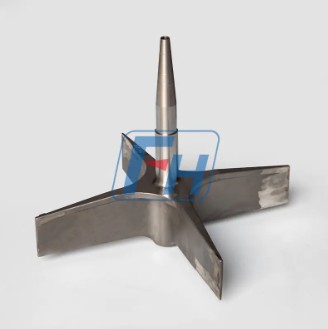

Through precise airflow guidance, the Furnace Fan Blades quickly circulate hot air within the furnace chamber, eliminating hot spots and ensuring uniform heating of each workpiece, improving heat treatment quality.

2. Improved production efficiency

Accelerated heat exchange and shortened heat treatment cycles increase production capacity and reduce energy consumption.

3. Reduced energy consumption

Optimized aerodynamic design reduces fan power requirements, helping companies achieve cost control.

4. Extended equipment life

FH uses lost wax casting technology, resulting in smooth blade surfaces and precise structure, reducing vibration and wear, and suitable for extremely high-temperature environments (up to 1200°C).

How to replace furnace fan blades?

1. Shut down and disconnect power

Turn off the furnace power and wait until the equipment cools to a safe temperature before operating.

2. Remove the old blades

Use a special wrench to loosen the fixing bolts and gently remove the old blades to prevent deformation caused by residual thermal stress.

3. Inspect the bearings and fan housing.

Before replacement, check the bearing lubrication and the housing for wear or cracks, performing maintenance if necessary.

4. Install the new blades.

Align the FH custom blades with the locating holes and tighten using a torque wrench to the manufacturer's recommended torque value, ensuring there is no misalignment.

5. Dynamic Balancing Verification

After completion, perform a dynamic balancing test to confirm that the blades are operating smoothly before restarting.

What are the differences between blades of different materials? Which is best for my furnace?

1. Selection Recommendations

Extremely high temperatures (>1000°C): Nickel-based alloys are recommended, as they maintain strength and oxidation resistance above 1250°C.

Medium-high temperatures (800-1000°C): Incoloy 800H or high-alloy steels are suitable, depending on cost and processing requirements.

For low temperatures or weight-sensitive applications: Aluminum alloy blades significantly reduce the moment of inertia and improve fan response speed.

2. Customization Service

FH's engineering team can tailor the most appropriate alloy formula based on your maximum operating temperature, media corrosiveness, and fan size, achieving the optimal balance between aerodynamics and durability.

| Material | Temperature Range | Strength / Hardness | Corrosion Resistance | Typical Applications |

| High‑Alloy Steel | Up to 1200 °C (conventional heat‑treatment) | High strength, wear‑resistant | Moderate | High‑temperature heat‑treatment, aerospace |

| Nickel‑Based Alloy (e.g., THERMET™ 22H) | 950 °C – 1250 °C | Very high strength, creep‑resistant | Excellent (resistant to carburizing & sulfiding) | Ultra‑high‑temperature furnaces, special‑alloy heat‑treatment |

| Aluminum Alloy (lightweight) | Up to 800 °C | Light, easy to machine | Fair | Medium/low‑temperature heat‑treatment, energy‑saving equipment |

| Incoloy 800H (Ni‑Cr alloy) | Up to 982 °C | High strength, good toughness | Good (oxidation‑resistant) | Long‑duration high‑temperature furnace components |

What should I do if my furnace fan blades vibrate?

1. Dynamic Balancing

Use a dynamic balancing instrument to remeasure the blades. If imbalance is detected, correct the balance or replace the unbalanced component.

2. Inspect the Mounting Bolts

Confirm that all bolts are tightened to the specified torque. Loose bolts can cause blade deflection and vibration.

3. Observe the Blade Surface

Inspect for cracks, corrosion, or surface defects, and replace damaged blades if necessary.

4. Bearing and Lubrication Assessment

Bearing wear or insufficient lubrication can also cause imbalance. Replace or refill the lubricant promptly.

5. On-site Diagnosis and Repair

FH offers on-site troubleshooting services, equipped with professional dynamic balancing equipment and experienced technicians, to quickly locate and resolve vibration issues and restore your equipment to optimal operation.

Selection Guide: How to Choose the Best Furnace Fan Blades for Your Heat Treating Furnace?

1. Determine the operating temperature

Select the appropriate material based on the furnace's maximum operating temperature (e.g., nickel-based alloy for 950-1250°C).

2. Calculate the required air volume

Based on the furnace chamber volume and heat load, use CFD (computational fluid dynamics) software or the air volume calculation table provided by FH to determine the number and size of blades.

3. Consider space constraints

For compact furnaces, lightweight aluminum alloy blades can reduce moment of inertia and improve start-up/shutdown response.

4. Evaluate lifespan and maintenance costs

High-alloy steel blades have a lifespan of 5-7 years at moderate temperatures, while nickel-based alloys can extend this to over 10 years, reducing replacement frequency.

5. Customization requirements

For special shapes or media (such as corrosive gases), FH can provide surface coatings or special alloy formulations.

FAQ Quick Troubleshooting Guide

| Symptom | Possible Cause | Recommended Action |

| Increased blade noise | Imbalance, bearing wear | Re‑balance the blade → replace bearing if needed |

| Hot spots inside furnace | Deteriorated aerodynamic performance, blade deformation | Inspect blade surface → replace if deformed |

| Abnormally high fan power consumption | Increased blade resistance, fouling | Clean blades → replace if corrosion is present |

| Vibration frequency mismatched with speed | Loose mounting bolts, misaligned installation | Tighten bolts → correct blade positioning |

| General vibration | Dynamic imbalance, loose bolts, worn bearings | Perform dynamic balancing → replace or re‑tighten components |

Fri 02, 2026

Fri 02, 2026

Thu 02, 2026

Thu 02, 2026