0086-13338774804

0086-13338774804

Get in Touch

Jan 12, 2026

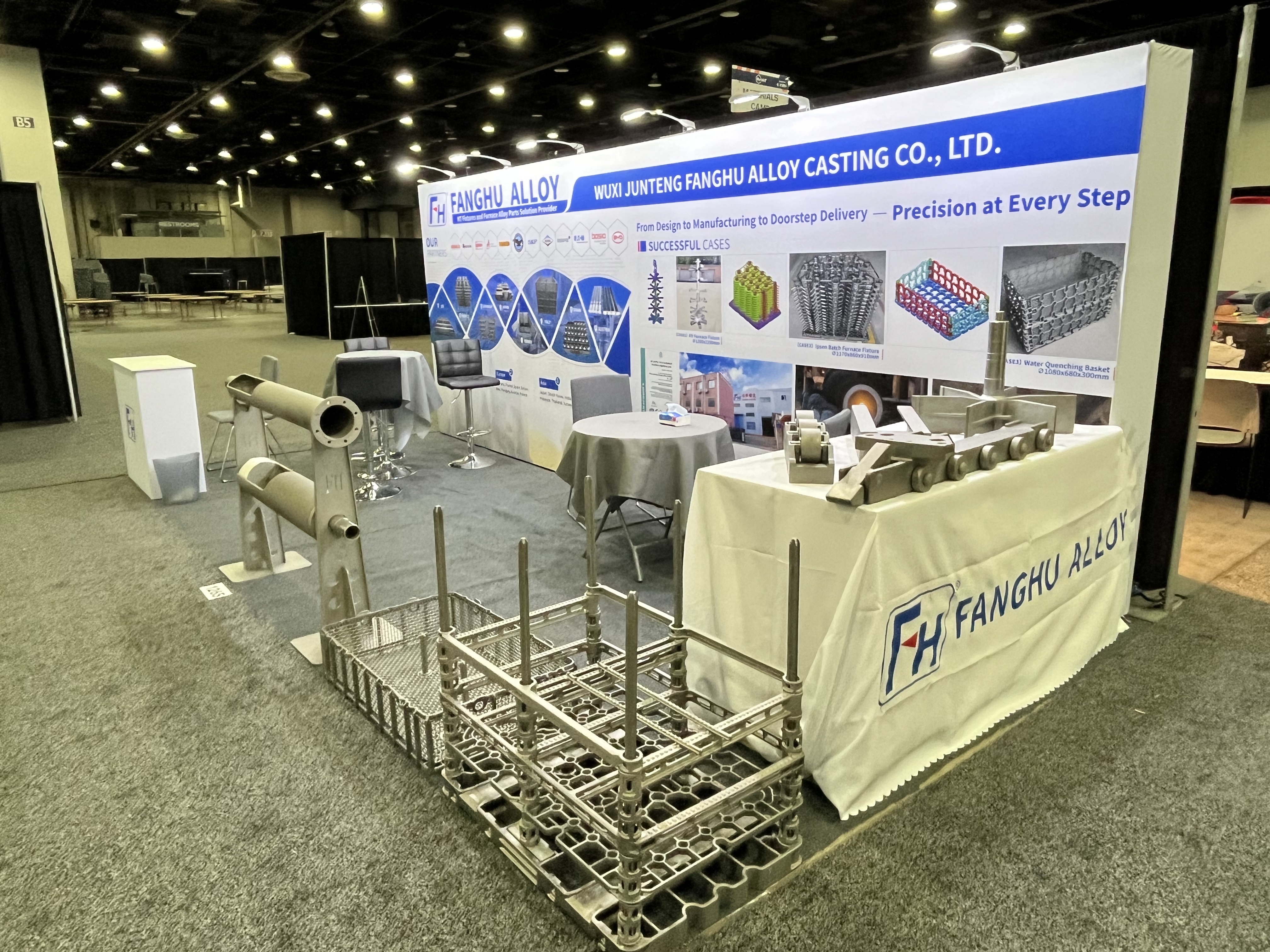

Jan 12, 2026 In the automotive manufacturing industry chain, heat treatment is a critical process that determines the performance of auto parts. Whether it is engine crankshafts, gearbox gears, wheel hub flanges, connecting rods or other core components, they all need to go through the core process flow of "heating - heat preservation - cooling" to improve hardness, toughness and wear resistance. Some precision parts also require additional strengthening processes such as carburizing and nitriding. The success of this process often relies on the "hard-core support" of heat treatment fixtures. As a professional brand focusing on high-temperature heat treatment equipment, FH's custom baskets and trays have become a key for many automakers and parts manufacturers to reduce costs and increase efficiency, thanks to their precise adaptability and stable performance, and can even achieve a significant reduction of 18% in defect rates.

Auto parts come in a wide variety of types and structures, ranging from precision gear rings to large wheel hub assemblies, from solid shaft parts to thin-walled shell parts. Different parts have distinct heat treatment requirements, which means that universal heat treatment fixtures are difficult to meet production needs. Traditional standardized baskets and trays often have many drawbacks: fixed spacing leads to overcrowded placement of parts, resulting in uneven heating during the heating stage (e.g., carburizing process requires continuous heating at 900-950℃) and prone to hardness deviation; unreasonable structural design causes parts to undergo micro-deformation due to self-weight or heat treatment fixtures extrusion during the heat preservation stage (usually 2-4 hours), and inconsistent cooling rates may occur due to fixture shielding during the cooling stage (oil cooling or air cooling), affecting the stability of the metallographic structure. These problems directly lead to high heat treatment defect rates, and FH custom baskets and trays are precisely developed to address these pain points.

FH® Heat Treatment Fixtures Exclusive Custom Solutions: Adapting to Heat Treatment Needs of Core Auto Parts

Based on the structural characteristics and process requirements of core auto parts, FH has created a series of exclusive custom heat treatment fixtures solutions, realizing an upgrade from single adaptation to full-process optimization:

Custom Heat Treatment Fixtures for Crankshafts

As the "heart" component of the engine, the crankshaft needs to withstand complex alternating loads. Its heat treatment must balance the hardness of the journal and the toughness of the crank arm. The commonly used process is quenching 42CrMo alloy steel at 850-900℃ followed by tempering at 400-450℃. FH custom heat treatment fixtures adopt a "three-point elastic support structure", with arc-shaped elastic gaskets set at the key parts of the main journal and connecting rod journal to avoid rigid extrusion deformation at high temperatures. The main body of the heat treatment fixtures is made of high-temperature resistant alloy materials, combined with a zoned heat dissipation channel design to ensure uniform heating of all parts of the crankshaft, with the nitriding layer depth controlled within the range of 50-100μm. After application by an engine manufacturer, the quenching deformation of the crankshaft was reduced from 0.3mm to 0.08mm, the fatigue life was increased by 40%, and the defect rate was reduced by 16%.

Custom Heat Treatment Trays for Wheel Hubs

Most wheel hubs are made of aluminum alloy or magnesium alloy materials. Heat treatment needs to solve the problem of high-temperature deformation of lightweight materials. In particular, new energy vehicle wheel hubs also need to meet the temperature stability requirements related to battery thermal management. FH® (Wuxi Junteng Fanghu Alloy Technology Co., Ltd.) custom heat treatment trays adopt a "hollow frame + flexible positioning pin" design, with positioning points accurately matched according to the wheel hub size to avoid clamping stress concentration. The bottom of the tray is optimized with ventilation structure to adapt to the rapid cooling demand of 120-240 seconds in the air cooling process, ensuring that the hardness uniformity of the wheel hub after quenching is increased by 25%. For rare earth magnesium alloy wheel hubs, the heat treatment fixture surface is sprayed with high-temperature lubricating coating to prevent adhesion during the 300℃ heat preservation stage. After application by a new energy vehicle manufacturer, the wheel hub scrap rate was reduced from 12% to 3%.

Custom Heat Treatment Fixtures System for Gears

The core requirement of gear heat treatment is to balance the high hardness of the tooth surface and the toughness of the tooth core. The commonly used process is carburizing at 900℃ followed by oil quenching, and it is necessary to control the residual magnetism to avoid affecting subsequent welding accuracy. FH® (Wuxi Junteng Fanghu Alloy Technology Co., Ltd.) custom heat treatment fixtures adopt a "layered and separated design", with a uniform gap of 3-5mm reserved between each tooth to ensure full penetration of the carburizing atmosphere. The heat treatment fixture has a built-in demagnetization auxiliary structure, which, combined with the precise layout of the high-frequency heating coil, reduces the residual magnetism of the gear synchronously after heat treatment to meet the welding process requirements. After use by a gearbox manufacturer, the tooth surface hardness of the gear reached HRC58-62, the tooth deformation was ≤0.03mm, and the defect rate was reduced from 22% to 4%, achieving a significant drop of 18%.

Core Advantages of FH Custom Baskets & Trays

The core competitiveness of FH® (Wuxi Junteng Fanghu Alloy Technology Co., Ltd.) custom baskets and trays stems from in-depth adaptation and technical optimization of the entire heat treatment process:

Quality Control and Customer Recognition

The reliability of FH custom heat treatment fixtures is backed by a sound quality control system. FH complies with the ISO 9001, ISO 14001 quality certification standard, strictly inspects material composition through a spectrum analyzer from the raw material procurement link, implements a "three-inspection system" during the production process, and controls the dimensional accuracy error within ±0.02mm. Before leaving the factory, the finished products undergo high-temperature simulation tests to replicate the actual heat treatment cycle of auto parts and verify the stability and durability of the fixtures. With such strict quality control, FH has become a long-term partner of well-known automakers such as SAIC and BYD, and its products cover the heat treatment scenarios of core parts for traditional fuel vehicles and new energy vehicles.

In today's era of high-end and precision-oriented transformation of automotive manufacturing, the "customization" of heat treatment fixtures has become a key measure to enhance core competitiveness. As a professional brand deeply engaged in the heat treatment equipment field, FH provides reliable heat treatment fixtures solutions for auto parts heat treatment through exclusive custom solutions for core parts such as crankshafts, wheel hubs and gears, combined with high-performance materials and strict quality control. For auto parts manufacturers, choosing FH custom baskets and trays can not only solve traditional problems such as uneven heating and part deformation but also achieve the cost reduction and efficiency increase effect of directly reducing defect rates. In the future, FH will continue to focus on the technological upgrading of automotive heat treatment processes, and provide more process-adaptive custom products to help global automotive enterprises achieve high-quality production.

Fri 02, 2026

Fri 02, 2026

Thu 02, 2026

Thu 02, 2026