What are the common repair methods for wear-resistant castings?

1. Surface Coating (Cladding): Plasma spraying or laser cladding is used to regenerate a high-hardness layer on the worn area, significantly improving wear resistance and restoring dimensional accuracy.

2. Welding Repair: Using low-hydrogen alkaline welding rods and a preheating-slow cooling process, the weld temperature is controlled at 250-300℃, achieving high-quality repair welding while maintaining material hardening properties.

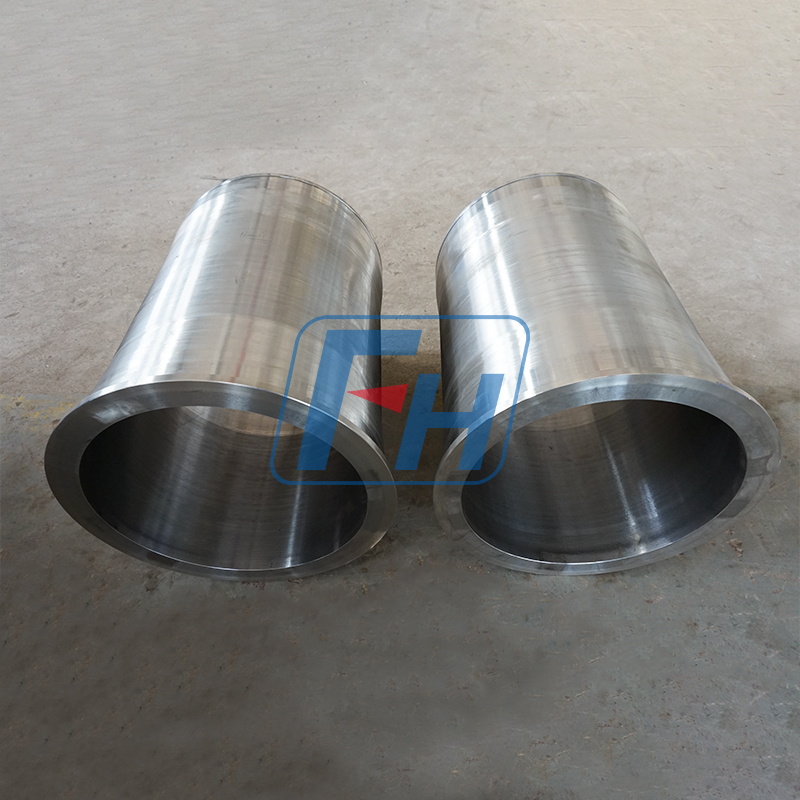

3. Machining and Polishing: Minorly worn castings undergo precision turning, grinding, or polishing to remove the damaged layer, followed by reheat treatment to restore original hardness and toughness.

4. Replacement of Damaged Parts: For areas with impact cracks or large-area spalling, directly replace with custom-made wear-resistant castings to avoid microstructural degradation caused by secondary heat treatment.

How to judge the quality of wear-resistant castings?

1. Macroscopic Microstructure Inspection: Observe the casting surface for coarse grains, cracks, or a decarburized layer. Coarse-grained structures often indicate insufficient wear resistance.

2. Hardness and Wear Resistance Testing: Hardness and wear resistance coefficients are quantified by Rockwell or Vickers hardness testing and ball-disc wear tests, compared to industry benchmarks (e.g., high manganese steel offers a 25-fold increase in wear resistance).

3. Chemical Composition and Alloy Element Distribution: Spectroscopic or EDS analysis is used to confirm the content of key alloying elements and their distribution at grain boundaries. A lack of these reinforcing phases can lead to accelerated wear.

4. Non-destructive Testing (Ultrasonic/Magnetic Particle) : Internal defects are detected by ultrasonic or magnetic particle testing to promptly identify internal cracks or porosity, preventing sudden failure under high loads.

How to Select Suitable Wear Resistant Castings for Impact, Abrasion, or High-Temperature Conditions?

1. Impact Load: Prioritize high-temperature alloy steels containing Cr-Al-Ni or high-manganese cast iron modified with rare earth metals (REMs), which provide better toughness and crack propagation resistance under impact.

2. Abrasive Environments: Laser cladding or plasma spraying with TiC, MoS₂, or WC-Ni composite powders forms hard carbides and self-lubricating phases, significantly reducing the coefficient of friction and mass loss.

3. High-Temperature Conditions: Using Cr-Al heat-resistant alloys or incorporating Al, Si, Nb, etc., into the matrix improves oxidation resistance and thermal stability, exhibiting excellent high-temperature performance, especially in heat treatment equipment above 1100℃.

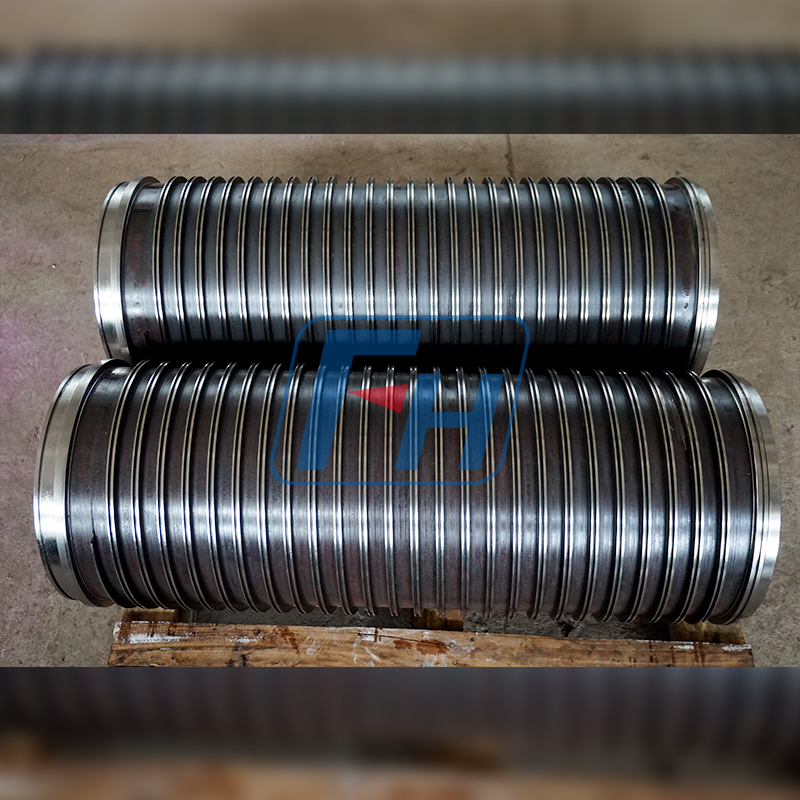

4. Overall Cost-Performance Ratio: Wuxi Junteng Fanghu Alloy Casting Co., Ltd., with casting experience since 2006, can provide OEM-customized wear-resistant castings based on customers' impact, abrasion, or high-temperature requirements. Through practical application cases of key products such as heat treatment fixtures, radiant tubes, and furnace rollers, we help customers optimize costs and improve process efficiency.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.