FH® Radiant Tubes | For Heat Treatment and Industrial Heating

Radiant tubes are essential components in heat treatment and industrial heating processes, widely used in metal hardening, annealing, tempering, and other high-temperature applications. They radiate heat evenly across the surface of the material being heated, ensuring precision and efficiency in the heating process. As a key element in heat treatment equipment, the quality of radiant tubes directly impacts heating performance and energy consumption.

Our FH® Series Radiant Tubes are specifically designed for industrial applications, offering superior high-temperature resistance, corrosion resistance, and long-lasting stability to ensure exceptional performance and efficient heat transfer even in extreme environments.

Key Features of FH® Series Radiant Tubes:

1. High-Efficiency Heat Transfer

The FH® Series radiant tubes are optimized for heat transfer efficiency, ensuring that heat is evenly distributed across the surface of the heated material. This not only improves heating efficiency but also reduces heat loss, thereby saving energy and lowering operating costs.

2. Exceptional High-Temperature Performance

These radiant tubes are made from high-temperature-resistant materials, capable of withstanding operating temperatures as high as 1200°C or even higher, making them ideal for applications requiring high-temperature processing.

3. Corrosion Resistance & Durability

The FH® Series radiant tubes are manufactured using advanced corrosion-resistant materials, allowing them to operate in high-temperature, corrosive atmospheres for extended periods. This greatly extends their lifespan and reduces the frequency of replacements.

4. Customizable Design

We offer a range of customization options for radiant tubes, allowing you to tailor them to the specific requirements of your industrial heating equipment. Whether you need different lengths, diameters, or special coatings, our radiant tubes can be designed to suit your exact specifications.

5. Energy-Efficient & Low Maintenance Costs

The design of the FH® Series radiant tubes not only maximizes heating efficiency but also minimizes maintenance and replacement costs. They are durable, easy to install and replace, and require less downtime, reducing overall maintenance expenses.

6. Wide Range of Applications

The FH® Series radiant tubes are used in a variety of industrial sectors, including:

- Heat Treatment: Ideal for metal hardening, annealing, and tempering processes.

- Metallurgical: Suitable for heating and metal treatment in the metallurgy industry.

- Ceramics and Glass Industry: Used in high-temperature furnaces for ceramic firing and glass production.

- Chemical and Petrochemical: Widely used in heating equipment and reaction furnaces.

Advantages of FH® Radiant Tubes:

- Improved Heating Efficiency: Optimized design ensures even heat distribution for consistent results.

- Reduced Energy Consumption: Minimizes heat loss, achieving better energy utilization and lowering heating costs.

- Extended Equipment Life: High-temperature and corrosion-resistant features allow for long-term use, reducing the need for frequent replacements.

- Custom Solutions: We provide professional custom radiant tube solutions to ensure a perfect fit with your heating system.

Why Choose FH® Series Radiant Tubes?

FH® Series Radiant Tubes are the ideal choice for your heat treatment equipment and industrial heating systems. Not only do we offer high-performance products, but we also provide comprehensive technical support and custom solutions. By choosing FH® radiant tubes, you will receive efficient, reliable, and cost-effective heating solutions that will help you stay ahead in the competitive market.

Quality Control: UT, MT, RT, PT, Chemical Analysis Report, Mechanical Property Test, etc.

If you're interested in our FH® Series Radiant Tubes, feel free to contact us for more information or to discuss your specific needs. We will provide personalized solutions to meet all your industrial heating requirements.

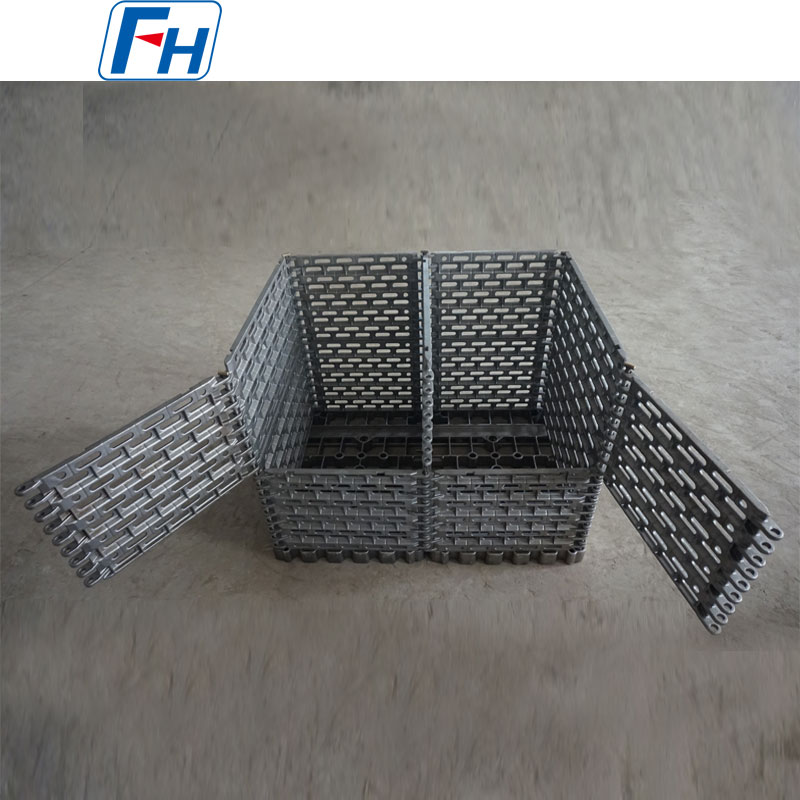

Genuine Photos of FH® Radiant Tubes:

Material Grade Table:

| Heat-resistant Steel | |||||||||||||

| / | GB | DIN | ASTM | JIS | Chemical Composition (%) | Maximum Operation Temperature | |||||||

| C | Si | Mn | Cr | Ni | Nb/Cb | Mo | Other | ||||||

| 1 | ZG40Cr27Ni4 | 1.4823 | HD | SCH11 | 0.30 - 0.50 | ≤2.00 | ≤1.00 | 24.00 - 28.00 | 4.00 - 6.00 | - | ≤0.50 | - | 1050℃ |

| 2 | ZG40Cr22Ni10 | 1.4826 | HF | SCH12 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 19.00 - 23.00 | 8.00 - 12.00 | - | ≤0.50 | - | 950℃ |

| 3 | ZG30Cr28Ni10 | - | HE | SCH17 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 8.00 - 11.00 | - | - | - | 1050℃ |

| 4 | ZG40Cr25Ni12 | 1.4837 | HH | SCH13 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 27.00 | 11.00 - 14.00 | - | ≤0.50 | - | 1050℃ |

| 5 | ZG30Cr28Ni16 | - | HI | SCH18 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 14.00 - 18.00 | - | - | - | 1100℃ |

| 6 | ZG40Cr25Ni20Si2 | 1.4848 | HK | SCH21 | 0.30 - 0.50 | ≤1.75 | ≤1.50 | 23.00 - 27.00 | 19.00 - 22.00 | - | ≤0.50 | - | 1100℃ |

| 7 | ZG30Cr20Ni25 | - | HN | SCH19 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 19.00 - 23.00 | 23.00 - 27.00 | - | - | - | 1100℃ |

| 8 | ZG40Cr19Ni39 | 1.4865 | HU | SCH20 | 0.35 - 0.75 | ≤2.50 | ≤2.00 | 17.00 - 21.00 | 37.00 - 41.00 | - | - | - | 1020℃ |

| 9 | ZG40Cr15Ni35 | 1.4806 | HT | SCH15 | 0.35 - 0.70 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1000℃ |

| 10 | ZG40Cr25Ni35Nb | 1.4852 | HPCb | SCH24Nb | 0.30 - 0.50 | ≤2.00 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | 0.80 - 1.80 | ≤0.50 | - | 1100℃ |

| 11 | ZG40Cr19Ni39Nb | 1.4849 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 18.00 - 21.00 | 36.00 - 39.00 | 1.20- 1.80 | ≤0.50 | - | 1100℃ |

| 12 | ZG40Cr24Ni24Nb | 1.4855 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 23.00 - 25.00 | 23.00 - 25.00 | 0.80 - 1.80 | ≤0.50 | - | 1050℃ |

| 13 | ZG40Cr25Ni35 | 1.4857 | HP | SCH24 | 0.35 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1100℃ |

| 14 | ZG1Cr20Ni32Nb | 1.4859 | - | - | 0.06 - 0.15 | 0.50 - 1.50 | ≤2.00 | 19.00 - 21.00 | 31.00 - 33.00 | 0.50 - 1.50 | ≤0.50 | - | 1050℃ |

| 15 | ZG45Cr12Ni60 | - | HW | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 10.00 - 14.00 | 58.00 - 62.00 | - | - | - | 1100℃ |

| 16 | ZG45Cr18Ni66 | - | HX | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 64.00 - 68.00 | - | - | - | 1100℃ |

| 17 | ZG1Cr28Co50 | 2.4778 | - | - | 0.05 - 0.25 | 0.50 - 1.00 | ≤1.50 | 27.00 - 30.00 | ≤1.00 | ≤0.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 18 | ZG30Cr28Co50Nb | 2.4779 | - | - | 0.25 - 0.35 | 0.50 - 1.50 | 0.50 - 1.50 | 27.00 - 29.00 | - | 1.50 - 2.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 19 | ZG40Cr28Ni48W5 | 2.4879 | - | SCH42 | 0.35 - 0.55 | 1.00 - 2.00 | ≤1.50 | 27.00 - 30.00 | 47.00 - 50.00 | - | ≤0.50 | W:4.0 - 5.5 | 1200℃ |

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.