FH® (Wuxi Junteng Fanghu Alloy Technology Co., Ltd.) is a professional manufacturer of heat treatment trays

FH® Heat Treatment Trays Detailed Introduction

Product Description:

FH® heat treatment trays are crafted from advanced high-temperature alloy materials, specifically designed for high-temperature, high-load industrial heat treatment environments. These trays are widely used in various heat treatment furnaces, including quenching furnaces, annealing furnaces, carburizing furnaces, and other industrial furnaces. They offer exceptional heat resistance, corrosion resistance, and superior mechanical strength, ensuring stable performance even under prolonged high-temperature operations without deforming or affecting the heat treatment process.

Key Features:

- Exceptional Heat Resistance: FH® heat treatment trays are made from high-temperature-resistant alloys, capable of withstanding temperatures up to 1200°C, ensuring excellent performance in extreme heat treatment conditions.

- High Load-Bearing Capacity: The design supports the transportation and support of heavy workpieces. The slots and frame structure ensure the stability of heat-treated workpieces, preventing displacement during heating.

- Corrosion Resistance: Special alloy components make the trays highly resistant to oxidation at high temperatures, effectively preventing metal corrosion and extending the service life.

- Wear Resistance: The tray surface is specially treated to enhance wear resistance, preventing damage or surface wear from prolonged use.

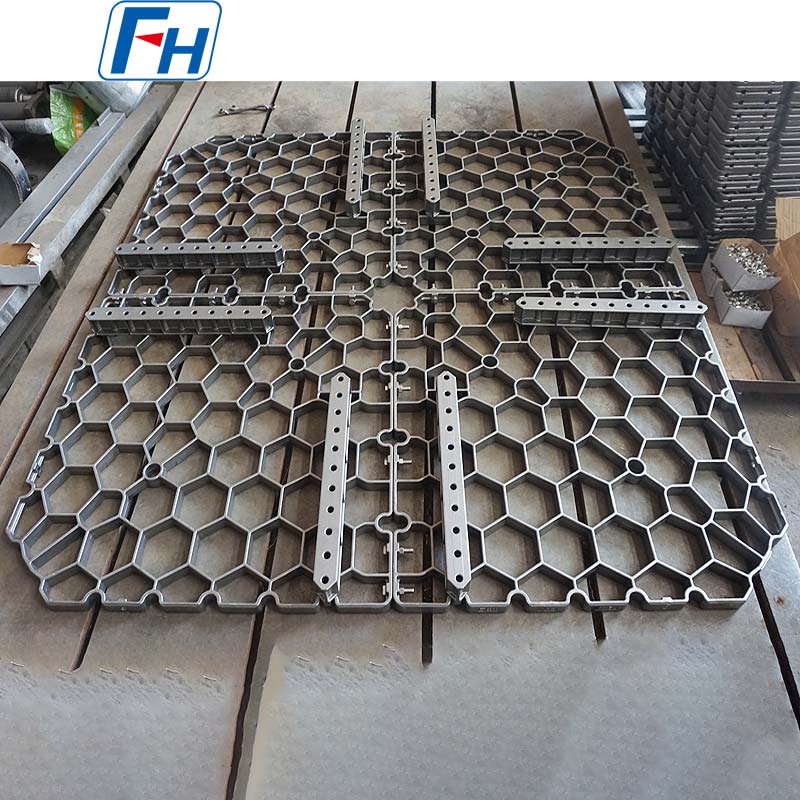

- Custom Design: FH® offers customized heat treatment trays according to customer requirements, providing tailored solutions for different workpiece shapes, sizes, and load-bearing needs.

Materials Used:

FH® heat treatment trays are primarily made from the following high-performance alloy materials:

- Cr25Ni20 Alloy: Suitable for high-temperature environments requiring superior heat resistance and corrosion resistance. It is commonly used in high-temperature heat treatment applications and offers excellent oxidation resistance and thermal fatigue performance.

- Heat-Resistant Steel (H13, AISI 4340): Ideal for high-strength, high-load applications, providing excellent toughness and wear resistance. Widely used in various heat treatment furnaces.

- High Chromium Alloys: Excellent oxidation resistance, capable of withstanding extreme high-temperature loads and prolonged thermal cycling.

Applications:

- Metal Processing: Widely used in the heat treatment of metal parts, especially in processes involving steel, aluminum alloys, copper alloys, and other materials. Ensures uniform hardness and stable quality of treated workpieces.

- Automotive Manufacturing: Used in the heat treatment of automotive components, particularly in engine parts, axles, and other high-strength parts, ensuring processing accuracy and surface quality.

- Aerospace: Used in the heat treatment of aerospace components, which require high strength, heat resistance, and long-term stability.

- Energy Sector: Applied in the heat treatment of high-temperature components and equipment in the energy industry, including nuclear power and thermal power generation.

Product Specifications:

- Materials: Cr25Ni20 Alloy, Heat-Resistant Steel (H13, AISI 4340), High-Chromium Alloys

- Size: Standard sizes and custom sizes (tailored to customer specifications)

- Load Capacity: Capable of supporting loads up to 1000 kg

- Temperature Resistance: Up to 1200°C

- Surface Treatment: High-temperature oxidation coating, wear-resistant coating

- Custom Design: Tailored to specific customer requirements for size, slots, and support structure

Product Advantages:

- Efficient Heat Conduction: The tray's optimized design ensures uniform heat distribution during the heat treatment process, improving efficiency and ensuring ideal heat treatment results for every workpiece.

- Thermal Fatigue Resistance: Made from special high-temperature alloys, the trays offer excellent resistance to thermal fatigue, ensuring long-lasting performance in high-temperature environments.

- Durable and Long-Lasting: Special surface treatments provide superior corrosion and wear resistance, enabling long-term use in harsh conditions.

- Low Maintenance Costs: The durable design reduces the frequency of replacements and maintenance, lowering operational costs and providing a higher return on investment.

Suitable Heat Treatment Processes:

- Quenching: Used in quenching processes for metals such as steel, where rapid cooling is employed to increase material hardness.

- Annealing: Applied in annealing processes to gradually heat and cool metals, improving their toughness and relieving internal stresses.

- Carburizing: Involves introducing carbon into the surface of the workpiece at high temperatures to enhance surface hardness and wear resistance.

Purchase Information:

FH® heat treatment trays provide reliable high-temperature heat treatment solutions for industries worldwide. For more information about our products, specifications, or custom requests, please contact our sales team. We will offer professional advice and high-quality after-sales support.

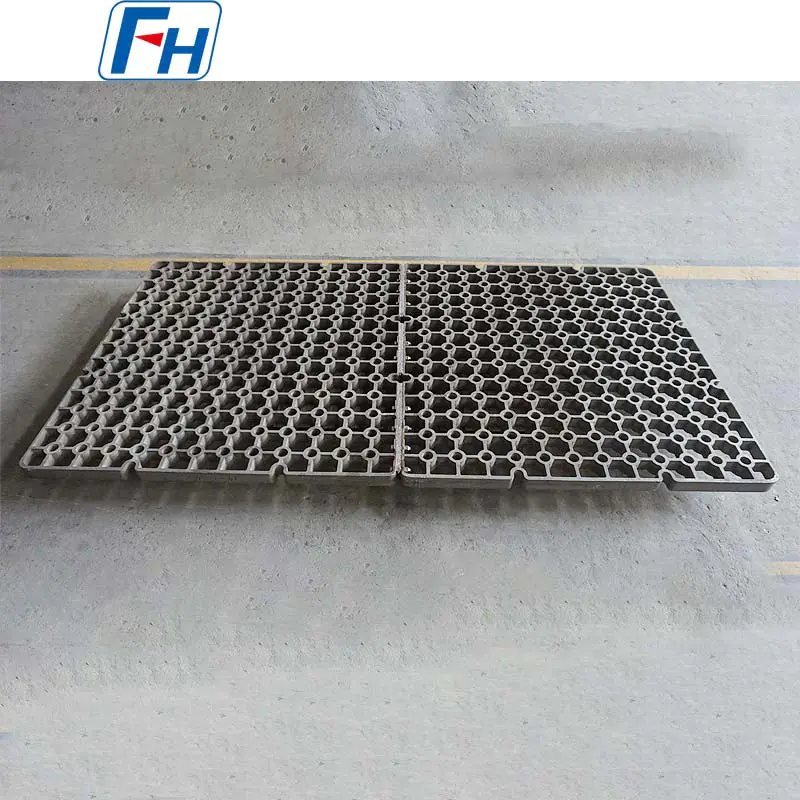

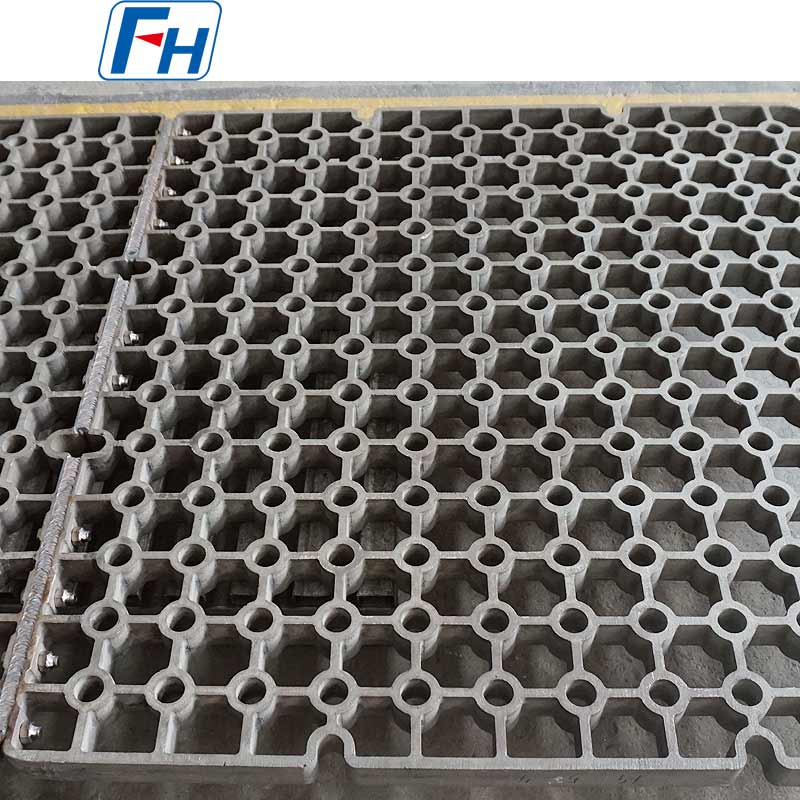

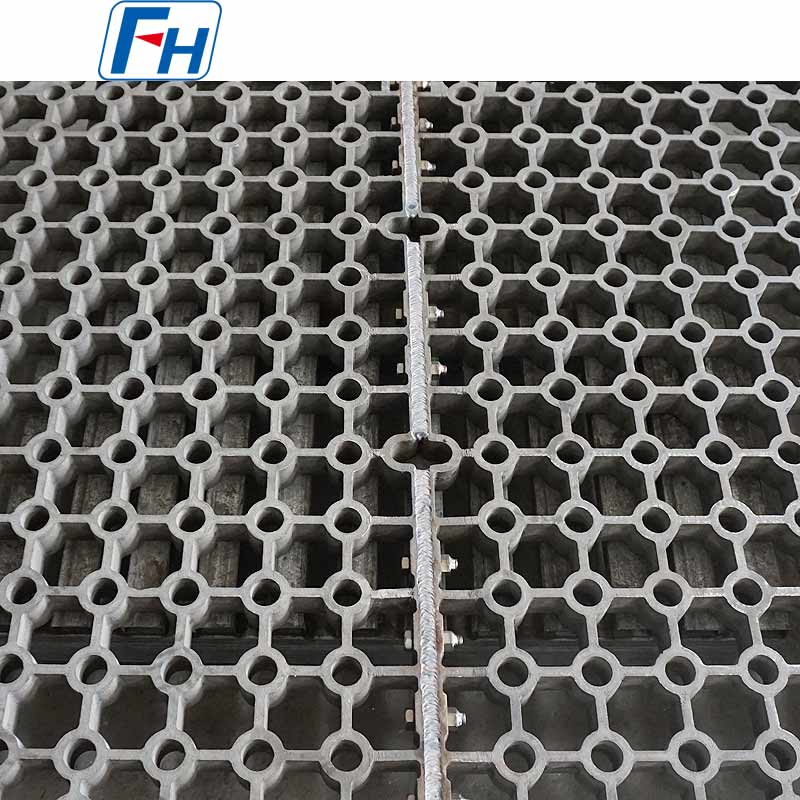

Genuine Photos of FH® Heat Treatment Trays:

Material Grade Table:

| Heat-resistant Steel | |||||||||||||

| / | GB | DIN | ASTM | JIS | Chemical Composition (%) | Maximum Operation Temperature | |||||||

| C | Si | Mn | Cr | Ni | Nb/Cb | Mo | Other | ||||||

| 1 | ZG40Cr27Ni4 | 1.4823 | HD | SCH11 | 0.30 - 0.50 | ≤2.00 | ≤1.00 | 24.00 - 28.00 | 4.00 - 6.00 | - | ≤0.50 | - | 1050℃ |

| 2 | ZG40Cr22Ni10 | 1.4826 | HF | SCH12 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 19.00 - 23.00 | 8.00 - 12.00 | - | ≤0.50 | - | 950℃ |

| 3 | ZG30Cr28Ni10 | - | HE | SCH17 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 8.00 - 11.00 | - | - | - | 1050℃ |

| 4 | ZG40Cr25Ni12 | 1.4837 | HH | SCH13 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 27.00 | 11.00 - 14.00 | - | ≤0.50 | - | 1050℃ |

| 5 | ZG30Cr28Ni16 | - | HI | SCH18 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 14.00 - 18.00 | - | - | - | 1100℃ |

| 6 | ZG40Cr25Ni20Si2 | 1.4848 | HK | SCH21 | 0.30 - 0.50 | ≤1.75 | ≤1.50 | 23.00 - 27.00 | 19.00 - 22.00 | - | ≤0.50 | - | 1100℃ |

| 7 | ZG30Cr20Ni25 | - | HN | SCH19 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 19.00 - 23.00 | 23.00 - 27.00 | - | - | - | 1100℃ |

| 8 | ZG40Cr19Ni39 | 1.4865 | HU | SCH20 | 0.35 - 0.75 | ≤2.50 | ≤2.00 | 17.00 - 21.00 | 37.00 - 41.00 | - | - | - | 1020℃ |

| 9 | ZG40Cr15Ni35 | 1.4806 | HT | SCH15 | 0.35 - 0.70 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1000℃ |

| 10 | ZG40Cr25Ni35Nb | 1.4852 | HPCb | SCH24Nb | 0.30 - 0.50 | ≤2.00 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | 0.80 - 1.80 | ≤0.50 | - | 1100℃ |

| 11 | ZG40Cr19Ni39Nb | 1.4849 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 18.00 - 21.00 | 36.00 - 39.00 | 1.20- 1.80 | ≤0.50 | - | 1100℃ |

| 12 | ZG40Cr24Ni24Nb | 1.4855 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 23.00 - 25.00 | 23.00 - 25.00 | 0.80 - 1.80 | ≤0.50 | - | 1050℃ |

| 13 | ZG40Cr25Ni35 | 1.4857 | HP | SCH24 | 0.35 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1100℃ |

| 14 | ZG1Cr20Ni32Nb | 1.4859 | - | - | 0.06 - 0.15 | 0.50 - 1.50 | ≤2.00 | 19.00 - 21.00 | 31.00 - 33.00 | 0.50 - 1.50 | ≤0.50 | - | 1050℃ |

| 15 | ZG45Cr12Ni60 | - | HW | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 10.00 - 14.00 | 58.00 - 62.00 | - | - | - | 1100℃ |

| 16 | ZG45Cr18Ni66 | - | HX | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 64.00 - 68.00 | - | - | - | 1100℃ |

| 17 | ZG1Cr28Co50 | 2.4778 | - | - | 0.05 - 0.25 | 0.50 - 1.00 | ≤1.50 | 27.00 - 30.00 | ≤1.00 | ≤0.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 18 | ZG30Cr28Co50Nb | 2.4779 | - | - | 0.25 - 0.35 | 0.50 - 1.50 | 0.50 - 1.50 | 27.00 - 29.00 | - | 1.50 - 2.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 19 | ZG40Cr28Ni48W5 | 2.4879 | - | SCH42 | 0.35 - 0.55 | 1.00 - 2.00 | ≤1.50 | 27.00 - 30.00 | 47.00 - 50.00 | - | ≤0.50 | W:4.0 - 5.5 | 1200℃ |

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.