FH® is the brand of Wuxi Junteng Fanghu Alloy Technology Co., Ltd., is a professional manufacturer of heat treatment racks and heat resistant alloy components for industrial furnaces.

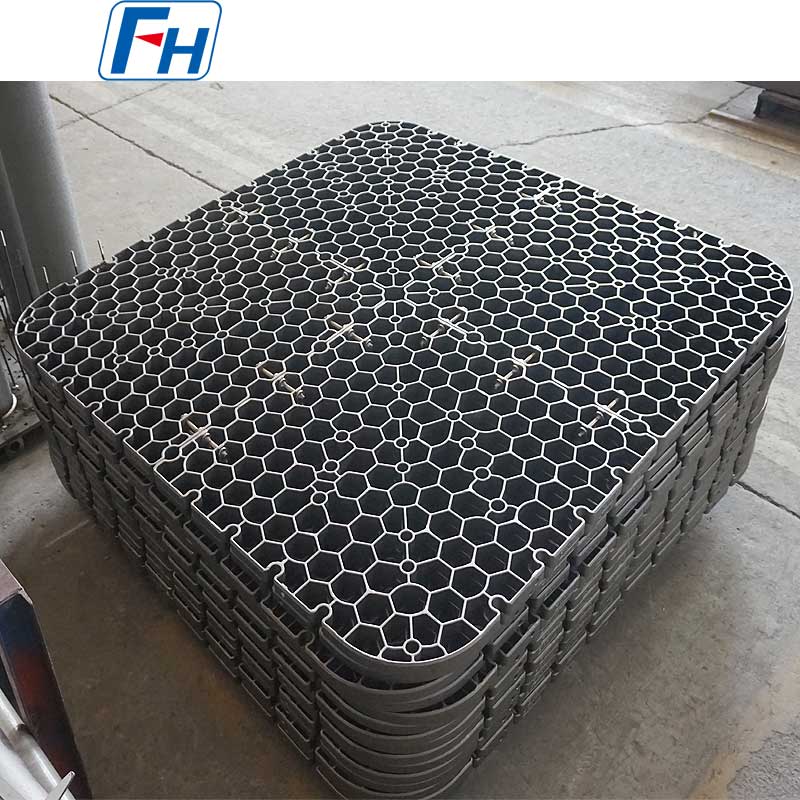

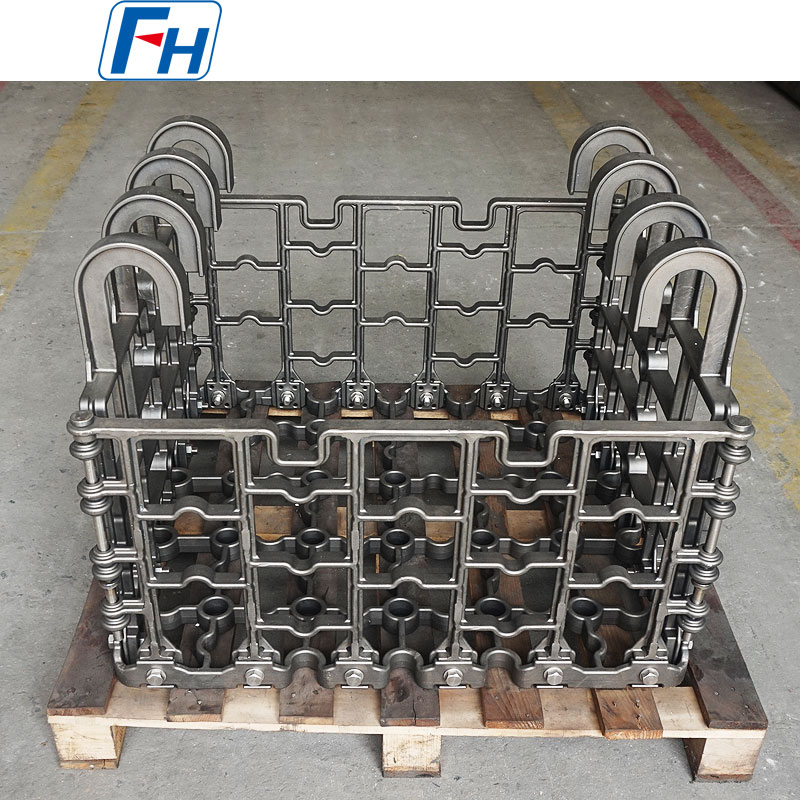

FH® Heat Treatment Racks Introduction:

FH® Heat treatment racks are essential equipment used in industrial furnaces to support and carry workpieces during heat treatment processes. They play a crucial role in ensuring the stability and uniform heating of the workpieces inside the furnace, which is vital for product quality and production efficiency.

1. Main Functions and Applications

The primary function of heat treatment racks is to bear the workpieces during the heat treatment process and provide the necessary support to maintain stable positioning in high-temperature environments. Different heat treatment processes (such as carburizing, nitriding, solution heat treatment, and tempering) have different requirements for the fixtures, and heat treatment racks are widely used in the following industries:

- Automotive Manufacturing: Used for heat treatment of automotive components such as gears, bearings, and engine parts.

- Aerospace: Used for high-precision heat treatment of aerospace components.

- Mold Manufacturing: Used for the heat treatment of metal molds and tools to improve wear resistance and hardness.

- Heavy Machinery & Equipment: Used for heat treating large components to enhance strength and fatigue resistance.

- Precision Manufacturing: Used for heat treatment of precision components like bearings and gears.

2. Materials and High-Temperature Performance

FH® Heat treatment racks are typically made from high-performance heat-resistant alloys that can withstand extreme high temperatures. Common heat-resistant materials include chromium alloys (Cr Alloy), nickel alloys (Ni Alloy), and refractory steel (Refractory Steel). These materials are capable of withstanding temperatures ranging from 800°C to 1200°C, ensuring that the racks remain stable and do not deform, break, or oxidize during heat treatment processes.

3. Structure and Design Features

The structural design of heat treatment racks directly impacts their load-bearing capacity and durability. High-quality racks are typically manufactured using precision welding techniques, ensuring strong seams and minimal thermal deformation. Common design features include:

- Adjustable Heights: To accommodate workpieces of varying sizes and weights.

- Stability: Optimized structures to prevent unnecessary deformation under high temperature and heavy load conditions.

- Corrosion Resistance: Racks are designed to resist corrosion from oxidation, oil residues, and other contaminants produced during the heat treatment process.

- Ease of Handling: Designed for easy transportation both inside and outside the furnace, often equipped with handles or trays.

4. Product Advantages

- High Temperature Stability: Heat-resistant alloy materials ensure the racks maintain stability under extreme temperatures without deforming or failing.

- Long Service Life: Made from wear-resistant, corrosion-resistant materials, racks offer an extended service life and reduced maintenance frequency.

- Optimized Processes: The scientifically designed structure allows for uniform heating of workpieces, avoiding significant temperature differences and improving the heat treatment results.

- Lower Costs: Reduced downtime, fewer replacements, and longer equipment and fixture lifespans contribute to lower overall operational costs.

5. Types and Customization Options

FH® Heat treatment racks come in various types depending on the heat treatment process and furnace model. These include:

- Standard Racks: Suitable for common heat treatment processes, offering simplicity and cost-effectiveness.

- Customized Racks: Designed to meet specific customer needs or accommodate uniquely shaped workpieces.

- Heavy-Duty Racks: Designed for workpieces that are heavier or larger, featuring reinforced structures to increase load-bearing capacity.

- Multi-Layer Racks: Capable of holding multiple layers of workpieces, optimizing the use of furnace space.

Conclusion

FH® Heat treatment racks are crucial components in the heat treatment process, directly affecting production efficiency, product quality, and cost control. With increasing demands for precision and efficiency in heat treatment, more and more manufacturers are choosing high-quality, heat-resistant, and customized heat treatment racks to meet the evolving needs of the industry.

FH® Heat Treatment Racks stand out for their exceptional high-temperature performance, durability, and stability, making them the preferred choice for leading global manufacturers in heat treatment processes. These racks help customers improve production efficiency, reduce operational costs, and ensure consistent heat treatment results.

Material Grade Table:

| Heat-resistant Steel | |||||||||||||

| / | GB | DIN | ASTM | JIS | Chemical Composition (%) | Maximum Operation Temperature | |||||||

| C | Si | Mn | Cr | Ni | Nb/Cb | Mo | Other | ||||||

| 1 | ZG40Cr27Ni4 | 1.4823 | HD | SCH11 | 0.30 - 0.50 | ≤2.00 | ≤1.00 | 24.00 - 28.00 | 4.00 - 6.00 | - | ≤0.50 | - | 1050℃ |

| 2 | ZG40Cr22Ni10 | 1.4826 | HF | SCH12 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 19.00 - 23.00 | 8.00 - 12.00 | - | ≤0.50 | - | 950℃ |

| 3 | ZG30Cr28Ni10 | - | HE | SCH17 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 8.00 - 11.00 | - | - | - | 1050℃ |

| 4 | ZG40Cr25Ni12 | 1.4837 | HH | SCH13 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 27.00 | 11.00 - 14.00 | - | ≤0.50 | - | 1050℃ |

| 5 | ZG30Cr28Ni16 | - | HI | SCH18 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 14.00 - 18.00 | - | - | - | 1100℃ |

| 6 | ZG40Cr25Ni20Si2 | 1.4848 | HK | SCH21 | 0.30 - 0.50 | ≤1.75 | ≤1.50 | 23.00 - 27.00 | 19.00 - 22.00 | - | ≤0.50 | - | 1100℃ |

| 7 | ZG30Cr20Ni25 | - | HN | SCH19 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 19.00 - 23.00 | 23.00 - 27.00 | - | - | - | 1100℃ |

| 8 | ZG40Cr19Ni39 | 1.4865 | HU | SCH20 | 0.35 - 0.75 | ≤2.50 | ≤2.00 | 17.00 - 21.00 | 37.00 - 41.00 | - | - | - | 1020℃ |

| 9 | ZG40Cr15Ni35 | 1.4806 | HT | SCH15 | 0.35 - 0.70 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1000℃ |

| 10 | ZG40Cr25Ni35Nb | 1.4852 | HPCb | SCH24Nb | 0.30 - 0.50 | ≤2.00 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | 0.80 - 1.80 | ≤0.50 | - | 1100℃ |

| 11 | ZG40Cr19Ni39Nb | 1.4849 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 18.00 - 21.00 | 36.00 - 39.00 | 1.20- 1.80 | ≤0.50 | - | 1100℃ |

| 12 | ZG40Cr24Ni24Nb | 1.4855 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 23.00 - 25.00 | 23.00 - 25.00 | 0.80 - 1.80 | ≤0.50 | - | 1050℃ |

| 13 | ZG40Cr25Ni35 | 1.4857 | HP | SCH24 | 0.35 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1100℃ |

| 14 | ZG1Cr20Ni32Nb | 1.4859 | - | - | 0.06 - 0.15 | 0.50 - 1.50 | ≤2.00 | 19.00 - 21.00 | 31.00 - 33.00 | 0.50 - 1.50 | ≤0.50 | - | 1050℃ |

| 15 | ZG45Cr12Ni60 | - | HW | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 10.00 - 14.00 | 58.00 - 62.00 | - | - | - | 1100℃ |

| 16 | ZG45Cr18Ni66 | - | HX | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 64.00 - 68.00 | - | - | - | 1100℃ |

| 17 | ZG1Cr28Co50 | 2.4778 | - | - | 0.05 - 0.25 | 0.50 - 1.00 | ≤1.50 | 27.00 - 30.00 | ≤1.00 | ≤0.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 18 | ZG30Cr28Co50Nb | 2.4779 | - | - | 0.25 - 0.35 | 0.50 - 1.50 | 0.50 - 1.50 | 27.00 - 29.00 | - | 1.50 - 2.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 19 | ZG40Cr28Ni48W5 | 2.4879 | - | SCH42 | 0.35 - 0.55 | 1.00 - 2.00 | ≤1.50 | 27.00 - 30.00 | 47.00 - 50.00 | - | ≤0.50 | W:4.0 - 5.5 | 1200℃ |

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.