What is a heat treatment fixture?

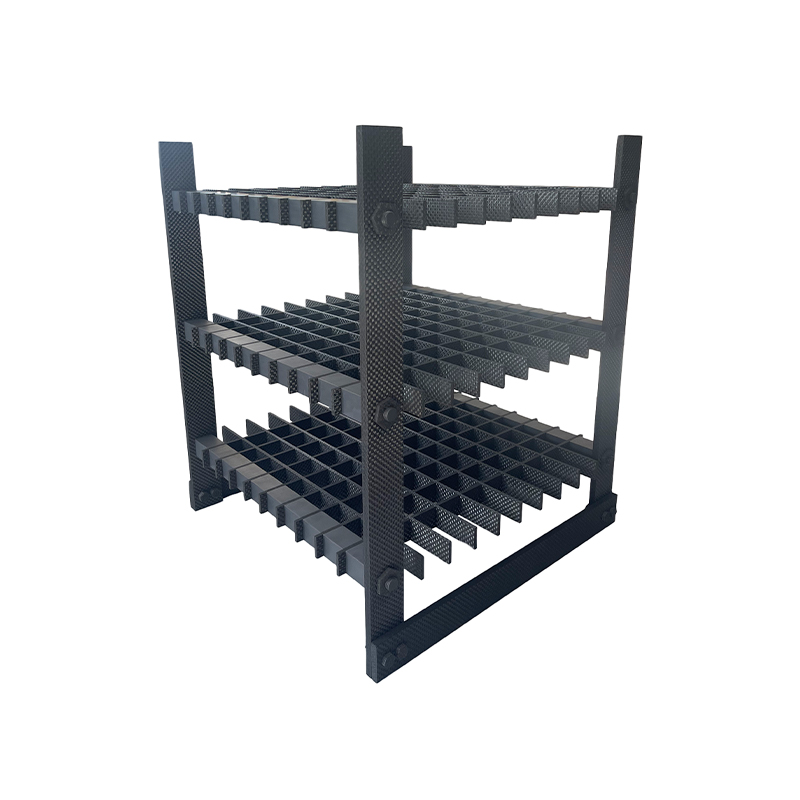

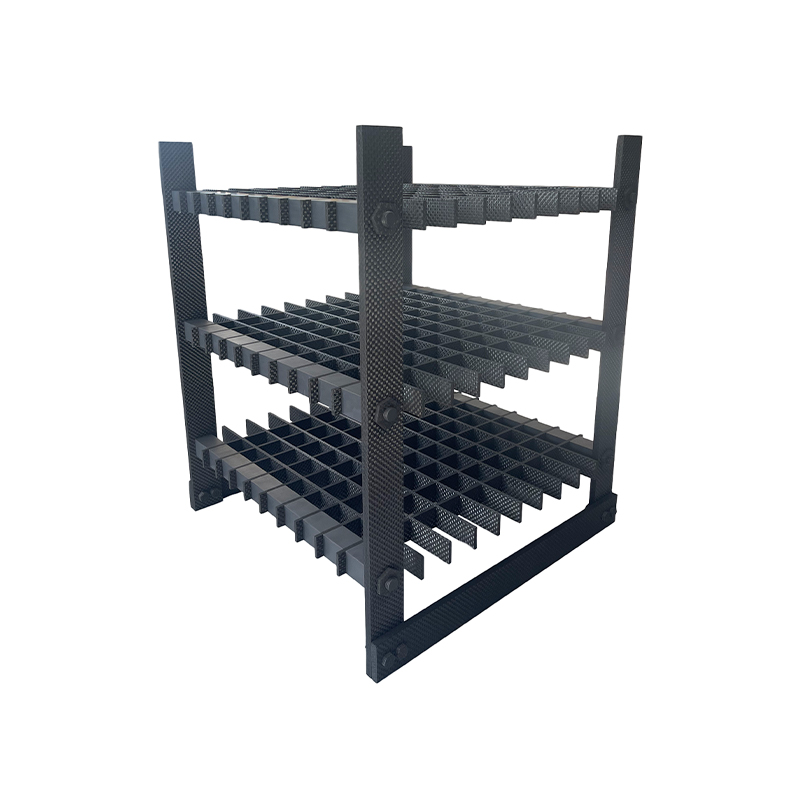

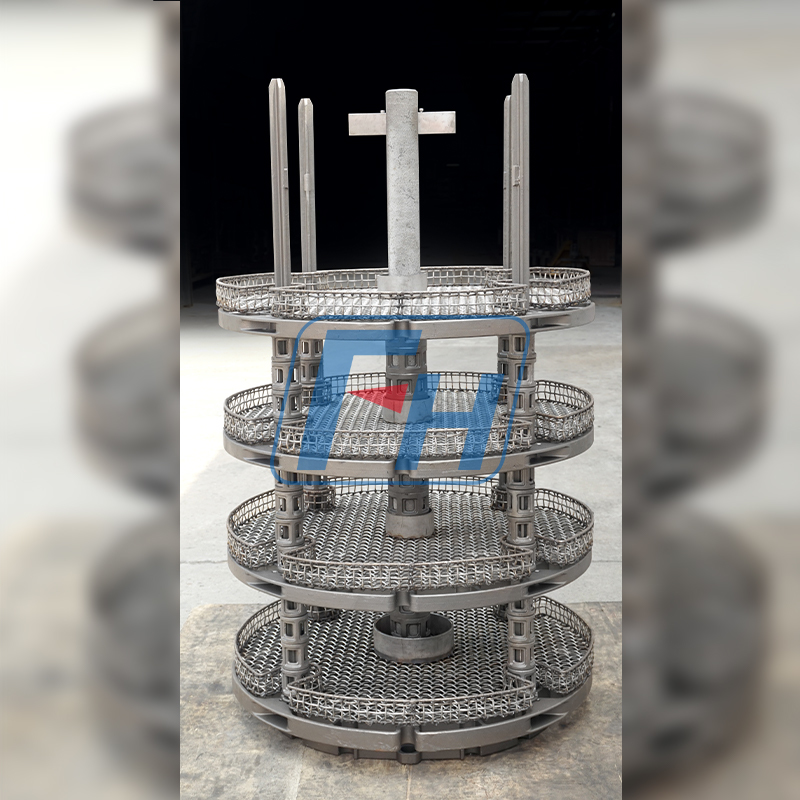

A heat treatment fixture is a supporting, positioning, and securing device designed specifically for use in high-temperature furnaces. It stabilizes the workpiece during the heat treatment process, prevents deformation, and ensures uniform heat flow.

1. Functional Positioning: Provides a reliable loading platform in a variety of furnace types, including vacuum, chamber, push-type, pit-type, and lamp-type furnaces (such as Ipsen, Aichelin, ECM, KGO, NITRIX, AFC, IVA-SCHEMTZ, CODERE, and MATTASA).

2. Structural Features: Utilizing a lost-wax casting process, it achieves a smooth and flat surface. Combined with a patented high-temperature-resistant alloy, it achieves long-term stability in extreme temperature cycling and corrosive environments.

3. Improved Efficiency: Through precise load design, it increases loading capacity, reduces rework due to workpiece movement, and significantly reduces heat treatment batch costs.

What are common heat treatment fixture materials?

High-temperature alloys – Based on the company's proprietary heat-resistant alloy formula, these materials maintain strength above 1200°C and are suitable for vacuum and high-temperature furnaces.

1. Carbon Fiber Reinforced Carbon (CFC) – Considered the industry benchmark in vacuum heat treatment, they offer excellent dimensional stability and significantly reduce workpiece distortion.

2. Refractory Ceramics and High-Temperature Steels – Commonly used in open furnaces or where flame impingement resistance is required, ensuring the fixture itself does not become a source of heat loss.

3. Specialty Coated Steels – Surface carburizing, nitriding, or plasma spraying enhances corrosion resistance and extends service life, making them suitable for oil or salt bath heat treatment environments.

What industries are Wuxi Junteng Fanghu Alloy Casting Co., Ltd.'s heat treatment fixtures primarily used in?

1. Automotive Manufacturing: We provide high-load, low-deformation fixture solutions for carburizing, nitriding, and vacuum heat treatment of engine components, gearboxes, and body structures, meeting the rigidity requirements of high-volume production. 2. Aerospace: Customized high-temperature alloy fixtures are used for high-strength alloy and titanium alloy components to ensure dimensional accuracy under extreme thermal cycles, improving the reliability of critical components.

3. Energy and Heavy Industry: Modular, multi-furnace compatible fixtures are used during the heat treatment of gas turbine blades, boiler pipes, and large castings, enabling rapid changeover and cost control.

4. Mold and Tool Manufacturing: Dedicated support structures are provided for mold heat treatment to prevent cracking or warping caused by thermal stress, extending mold life and improving product quality.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0086-510-88331288

Tel: 0086-510-88331288  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.