How to determine if an Other Heat-resistant Steel Part possesses high-temperature resistance?

1. High-Temperature Hardness and Strength Testing: Measure hardness using a Vickers or Shore hardness tester at operating temperatures such as 600°C and 800°C. Hardness remaining within the design range indicates sufficient strength at high temperatures.

Simultaneously perform high-temperature tensile or yield strength tests and record the stress-strain curve to ensure good elongation at the target temperature.

2. Magnetic Particle Examination: Magnetic particle examination of martensitic or ferritic alloys can quickly detect internal cracks, incomplete penetration, or heat treatment defects, which are often precursors to high-temperature failure.

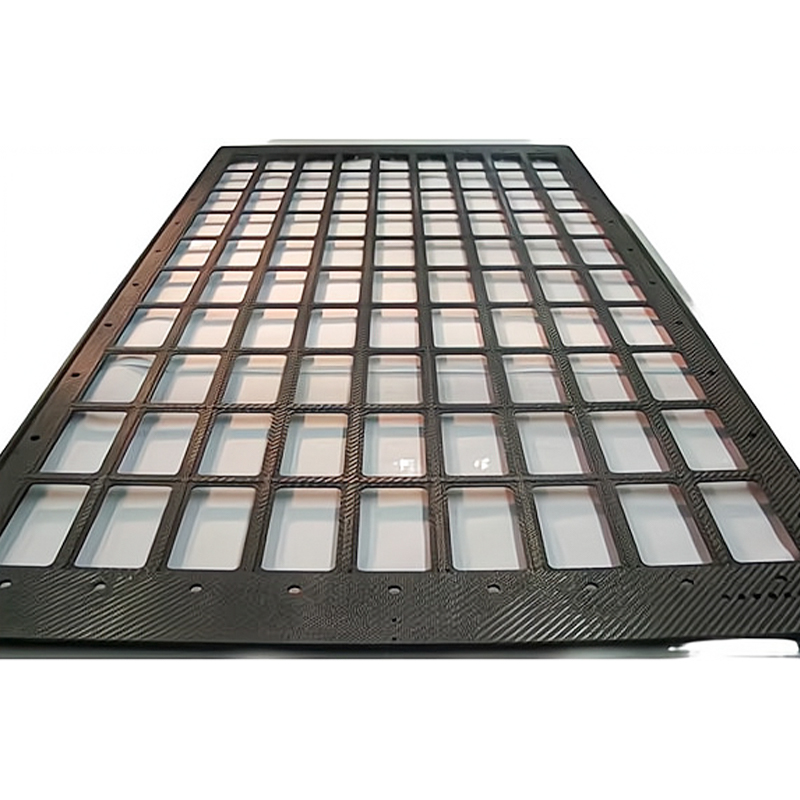

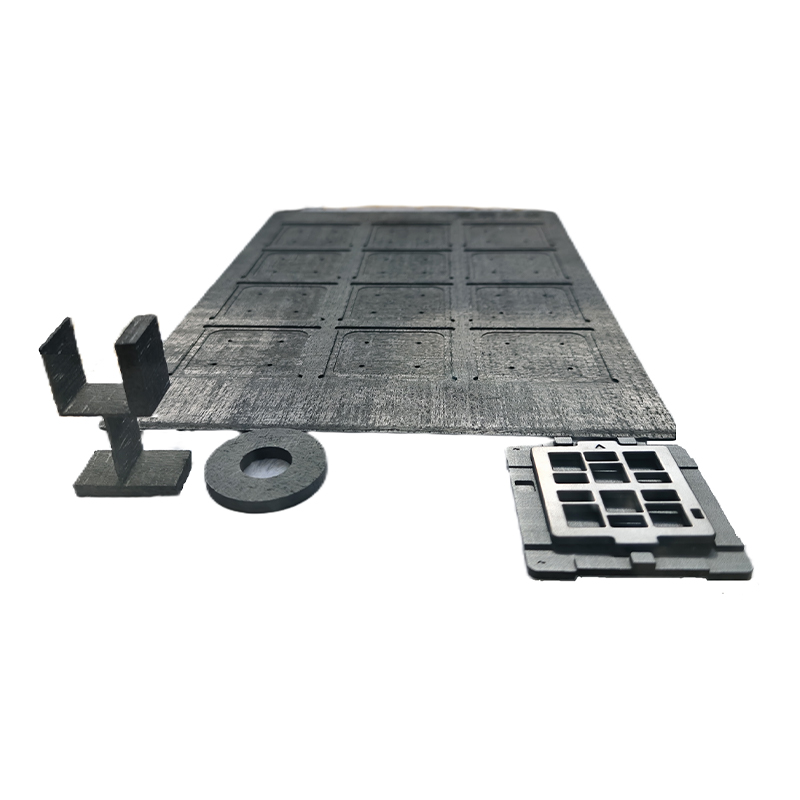

3. Liquid Penetrant Examination: Coating the surface with a penetrant and developing it allows for the detection of minute surface cracks or pores, particularly suitable for complex geometries such as heat-treated fixtures and radiant tubes.

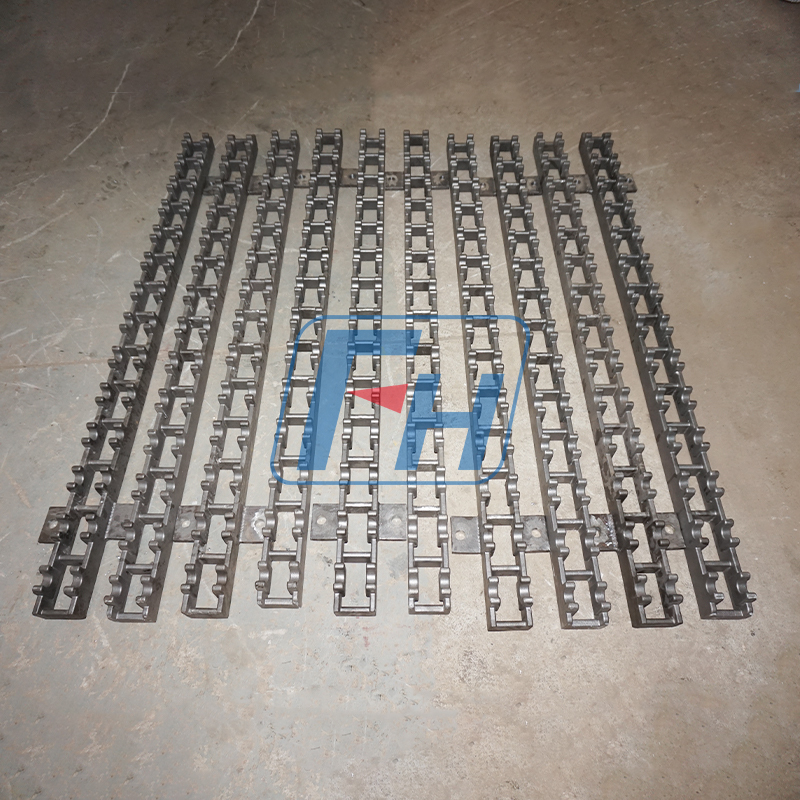

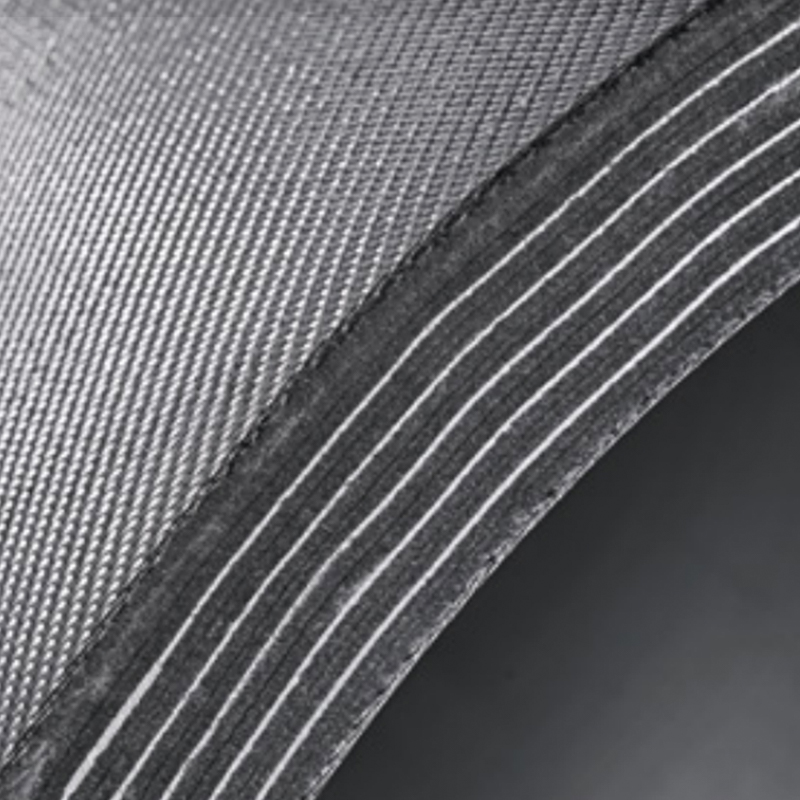

4. Ultrasonic or Phased Array Inspection: Ultrasonic testing assesses internal defects, interlayer debonding, or weld quality using time-of-flight or echo attenuation. Suitable for large components such as thick furnace rollers and furnace rails.

How to prevent cracking or deformation in Other Heat-resistant Steel Parts during high-temperature processing (e.g., heat treatment, welding)?

1. Reasonable Preheating and Uniform Heating: Use segmented preheating to reduce the temperature gradient and prevent surface cracking due to thermal shock.

2. Controlled Cooling Rate and Stress Relief: Use slow cooling or segmented air cooling to keep residual stress below 0.2%; if necessary, perform low-temperature tempering to relieve stress.

3. Welding Process Optimization: Use low-heat-input TIG/EB welding, followed by post-weld heat treatment to reduce hardening in the weld zone and prevent brittle cracking caused by hardening.

4. Surface Protection and Oxide Layer Management: Pre-oxidize the workpiece before high-temperature treatment or apply a high-temperature resistant ceramic coating to maintain a dense oxide film and prevent liquid metal penetration that could cause cracks.

5. Geometric Design and Stress Concentration Control: Avoid sharp corners and abrupt cross-sectional changes. Use rounded corners or transition sections to reduce local stress concentration and significantly decrease the probability of crack initiation.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0086-510-88331288

Tel: 0086-510-88331288  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.