Furnace Rollers:

Furnace rollers are core functional components used to carry and transport high-temperature materials in industrial furnaces (such as heat treatment furnaces, annealing furnaces, and glass melting furnaces). Their performance directly determines production continuity, material processing quality, and equipment efficiency. They are widely applicable to high-temperature industrial applications such as steel, glass, ceramics, and non-ferrous metals.

Material Transport: Through rotational motion, they smoothly transport materials such as steel plates, raw glass sheets, and ceramic bodies to the heating, annealing, and cooling areas within the furnace, ensuring continuous production.

Operating Conditions: They are exposed to high temperatures of 400-1200°C (up to 1500°C in some applications), and must withstand the weight of the materials, thermal shock, and corrosive gases within the furnace (such as oxidizing atmospheres and sulfur-containing gases). In some applications, they also require auxiliary temperature control (e.g., cooling with water-cooled rollers or supplementary heating with electrically heated rollers).

Quality Assurance: The flatness, roughness, and thermal stability of the roller surface directly impact the surface quality of the material (e.g., no indentations on steel plates or scratches on glass) and uniform heating.

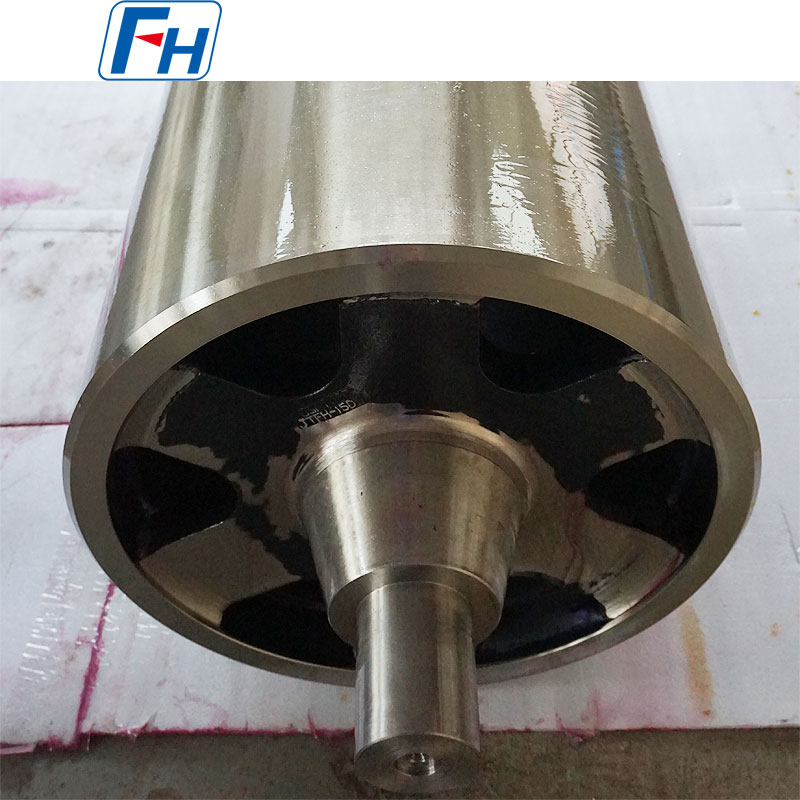

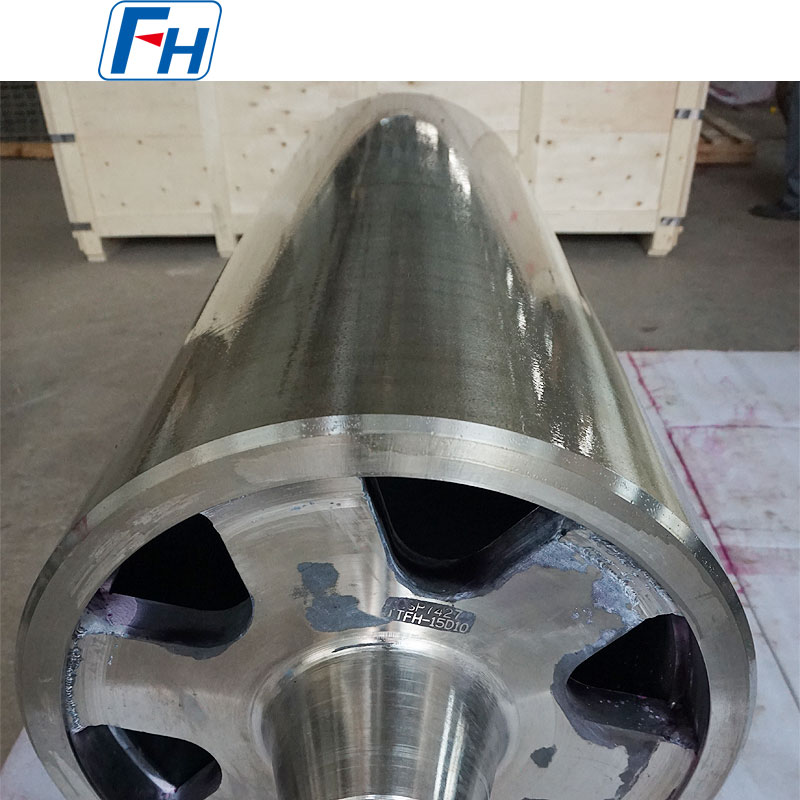

Furnace rollers are often composite structures, with the following core components:

Roller Sleeves: The outer layer of the roller that directly contacts the material and must exhibit high wear resistance, anti-adhesion properties, and high-temperature oxidation resistance. Common materials include heat-resistant steel, high-nickel alloys, or ceramic coatings.

Core Shafts: The inner layer of the roller sleeve that supports the roller sleeve and transmits rotational power. These shafts must provide a balance of strength and heat resistance. Some applications (such as high-temperature furnaces) may utilize hollow structures to allow for the passage of cooling media (e.g., water or nitrogen).

Support Components: These include bearings and seals, which must maintain lubricity and sealing properties even in high-temperature environments to prevent furnace gas leakage and dust from entering the bearings.

Common Classifications (by Function/Working Condition):

| Classification Criterion | Specific Type | Application Scenario |

| Cooling Method | Water-cooled furnace roller, Naturally cooled furnace roller | High-temperature heat treatment furnaces (e.g., steel annealing furnaces), glass forming furnaces |

| Heating Function | Electrically heated furnace roller, Ordinary furnace roller | Material conveyance requiring local supplementary heating (e.g., film heating) |

| Material/Surface Treatment | Ceramic-coated furnace roller, Nitrided furnace roller | Anti-adhesion scenarios (e.g., galvanized steel plate conveyance), high-wear scenarios |

| Structural Form | Hollow furnace roller, Solid furnace roller | Lightweight requirements (hollow), high-load requirements (solid) |

Application Fields:

Iron and Steel Industry: Cold-rolled continuous annealing furnaces, hot-dip galvanizing units, and section steel heating furnaces. They are used to convey steel plates and billets and need to withstand high temperatures of 800-1100°C and oxidizing atmospheres.

Glass Industry: Float glass forming furnaces and glass annealing furnaces. The roll surface must be smooth and free of impurities to avoid scratching glass sheets, with temperature adaptation of 600-1000°C.

Ceramics/Building Materials: Ceramic green body sintering furnaces and refractory material roasting furnaces. They need to resist material wear and high-temperature dust erosion.

Non-Ferrous Metals: Aluminum profile aging furnaces and copper strip annealing furnaces. They need to balance lightweight and high-temperature resistance (500-800°C).

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0086-510-88331288

Tel: 0086-510-88331288  E-mail:

E-mail:  Add: No.26 Baoyuan road, Section B Yangjian Industrial Park, Wuxi, Jiangsu, P.R. China P.C.:214107.

Add: No.26 Baoyuan road, Section B Yangjian Industrial Park, Wuxi, Jiangsu, P.R. China P.C.:214107.