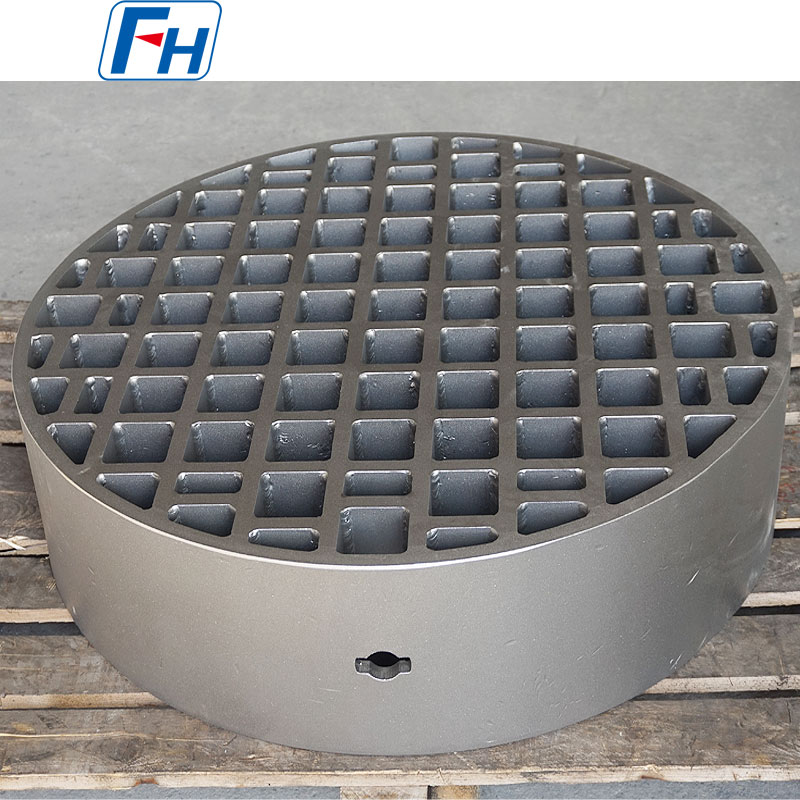

Heat-Resistant Steel Reaction Vessel – High-Temperature, High-Pressure, Corrosion-Resistant Industrial Solution

Product Introduction:

Our heat-resistant steel reaction vessels are crafted using advanced heat-resistant alloy materials, specifically designed for high-temperature, high-pressure, and corrosive environments. They are widely used in industries such as chemicals, petrochemicals, metallurgy, and power generation. The reaction vessel can withstand harsh chemical reaction conditions, providing a stable and efficient reaction environment to ensure product quality and production safety.

Key Features:

- Exceptional High-Temperature Resistance: Our heat-resistant steel reaction vessels can withstand temperatures up to 1000°C to 1200°C, suitable for high-temperature chemical reactions and catalytic processes.

- Superior Corrosion Resistance: Made from high chromium and nickel alloy materials, these vessels are resistant to acids, alkalis, salts, and other corrosive media, maintaining stable performance over time.

- High Strength and Pressure Resistance: The design allows for pressure capabilities of up to 50MPa, making it suitable for high-pressure reaction environments.

- Precise Temperature and Pressure Control Systems: Equipped with temperature and pressure regulation systems, ensuring precise control over the reaction conditions and improving reaction efficiency.

- Safety Assurance: Features pressure relief valves, temperature control systems, and sealed designs to ensure safety during reactions, preventing leaks and explosion risks.

Product Advantages:

- Wide Application in Harsh Reaction Environments: Suitable for chemical synthesis, petrochemical refining, metallurgy, pharmaceuticals, and food processing, offering high-efficiency, safe reaction conditions.

- Customizable Design: Various sizes, specifications, and configurations are available to meet specific customer needs.

- Durability: Heat-resistant steel's corrosion resistance and oxidation resistance offer an extended service life, reducing replacement and maintenance costs.

- Energy-Efficient and Environmentally Friendly: The efficient heat management system reduces energy consumption and waste, enhancing overall production efficiency.

Applications:

- Chemical Industry: Used for catalyst reactions, polymerization reactions, hydrogenation reactions, and more.

- Petrochemical and Natural Gas: Widely used in oil refining, gas treatment, and chemical synthesis.

- Metallurgical Industry: Suitable for high-temperature metal smelting and processing.

- Pharmaceutical Industry: Used in drug synthesis, chemical reactions, fermentation, and more.

- Food Processing: Involved in high-temperature cooking, reaction, and extraction processes.

Technical Specifications:

- Material: Cr25Ni20 / Inconel 625 and other high-temperature alloy steels

- Volume: 100L - 5000L (Customizable)

- Max Working Temperature: 1000°C - 1200°C

- Max Working Pressure: 15MPa - 50MPa (Adjustable)

- Stirring Type: Mechanical stirring, gas stirring (Optional)

- Control System: Digital temperature control, pressure sensors, automatic adjustment system

Purchase Advantages:

- Custom Services: We offer custom sizes and configurations of reaction vessels according to customer requirements, ensuring optimal fit for different reactions.

- Quality Assurance: All products undergo strict quality testing to meet international standards, offering long-term warranties and technical support.

- Fast Delivery: Efficient production and logistics teams ensure on-time delivery for your orders.

Wuxi Junteng Fanghu Alloy Technology Co., Ltd.(FH®) is a professional manufacturer of reaction vessel and heat resistant alloy components for industrial furnaces.

Material Grade Table:

| Heat-resistant Steel | |||||||||||||

| / | GB | DIN | ASTM | JIS | Chemical Composition (%) | Maximum Operation Temperature | |||||||

| C | Si | Mn | Cr | Ni | Nb/Cb | Mo | Other | ||||||

| 1 | ZG40Cr27Ni4 | 1.4823 | HD | SCH11 | 0.30 - 0.50 | ≤2.00 | ≤1.00 | 24.00 - 28.00 | 4.00 - 6.00 | - | ≤0.50 | - | 1050℃ |

| 2 | ZG40Cr22Ni10 | 1.4826 | HF | SCH12 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 19.00 - 23.00 | 8.00 - 12.00 | - | ≤0.50 | - | 950℃ |

| 3 | ZG30Cr28Ni10 | - | HE | SCH17 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 8.00 - 11.00 | - | - | - | 1050℃ |

| 4 | ZG40Cr25Ni12 | 1.4837 | HH | SCH13 | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 27.00 | 11.00 - 14.00 | - | ≤0.50 | - | 1050℃ |

| 5 | ZG30Cr28Ni16 | - | HI | SCH18 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 26.00 - 30.00 | 14.00 - 18.00 | - | - | - | 1100℃ |

| 6 | ZG40Cr25Ni20Si2 | 1.4848 | HK | SCH21 | 0.30 - 0.50 | ≤1.75 | ≤1.50 | 23.00 - 27.00 | 19.00 - 22.00 | - | ≤0.50 | - | 1100℃ |

| 7 | ZG30Cr20Ni25 | - | HN | SCH19 | 0.20 - 0.50 | ≤2.00 | ≤2.00 | 19.00 - 23.00 | 23.00 - 27.00 | - | - | - | 1100℃ |

| 8 | ZG40Cr19Ni39 | 1.4865 | HU | SCH20 | 0.35 - 0.75 | ≤2.50 | ≤2.00 | 17.00 - 21.00 | 37.00 - 41.00 | - | - | - | 1020℃ |

| 9 | ZG40Cr15Ni35 | 1.4806 | HT | SCH15 | 0.35 - 0.70 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1000℃ |

| 10 | ZG40Cr25Ni35Nb | 1.4852 | HPCb | SCH24Nb | 0.30 - 0.50 | ≤2.00 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | 0.80 - 1.80 | ≤0.50 | - | 1100℃ |

| 11 | ZG40Cr19Ni39Nb | 1.4849 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 18.00 - 21.00 | 36.00 - 39.00 | 1.20- 1.80 | ≤0.50 | - | 1100℃ |

| 12 | ZG40Cr24Ni24Nb | 1.4855 | - | - | 0.30 - 0.50 | 1.00 - 2.50 | ≤2.00 | 23.00 - 25.00 | 23.00 - 25.00 | 0.80 - 1.80 | ≤0.50 | - | 1050℃ |

| 13 | ZG40Cr25Ni35 | 1.4857 | HP | SCH24 | 0.35 - 0.50 | 1.00 - 2.50 | ≤2.00 | 24.00 - 28.00 | 33.00 - 37.00 | - | ≤0.50 | - | 1100℃ |

| 14 | ZG1Cr20Ni32Nb | 1.4859 | - | - | 0.06 - 0.15 | 0.50 - 1.50 | ≤2.00 | 19.00 - 21.00 | 31.00 - 33.00 | 0.50 - 1.50 | ≤0.50 | - | 1050℃ |

| 15 | ZG45Cr12Ni60 | - | HW | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 10.00 - 14.00 | 58.00 - 62.00 | - | - | - | 1100℃ |

| 16 | ZG45Cr18Ni66 | - | HX | - | 0.35 - 0.75 | ≤2.00 | ≤2.00 | 15.00 - 19.00 | 64.00 - 68.00 | - | - | - | 1100℃ |

| 17 | ZG1Cr28Co50 | 2.4778 | - | - | 0.05 - 0.25 | 0.50 - 1.00 | ≤1.50 | 27.00 - 30.00 | ≤1.00 | ≤0.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 18 | ZG30Cr28Co50Nb | 2.4779 | - | - | 0.25 - 0.35 | 0.50 - 1.50 | 0.50 - 1.50 | 27.00 - 29.00 | - | 1.50 - 2.50 | ≤0.50 | Co:48.0 - 52.0 | 1200℃ |

| 19 | ZG40Cr28Ni48W5 | 2.4879 | - | SCH42 | 0.35 - 0.55 | 1.00 - 2.00 | ≤1.50 | 27.00 - 30.00 | 47.00 - 50.00 | - | ≤0.50 | W:4.0 - 5.5 | 1200℃ |

FAQ:

Q: How to give inquiry ?

A: Step 1, please give us some details about your furnace,operating temperature,cooling method,loading weight of your furnace and so on;

Step 2, it's better to provide 3D drawings;

Step 3, when we have enough details, we may design the products drawings and quote accordingly;

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: When will make delivery ? /What is the delivery Time?

A: -Sample Order: 35 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 30 days after receipt of the deposit.

Q: What's your after-sales service?

A: 1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

Q: What's your payment condition?

A: T/T

Payment<=USD10000, 100% in advance. Payment>USD10000, 50% T/T in advance ,balance before shipment.

Q: What is the shipping method?

A: Transported by DHL, UPS, EMS, Fedex,Air freight, sea freight or train freight.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0510-83310100

Tel: 0510-83310100  E-mail:

E-mail:  Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.

Add: Room 1105,Building 6, Jiaye Wealth Center,Wuxi, Jiangsu, P.R.China P.C.:214000.