What is a chain plate in a chain casting furnace?

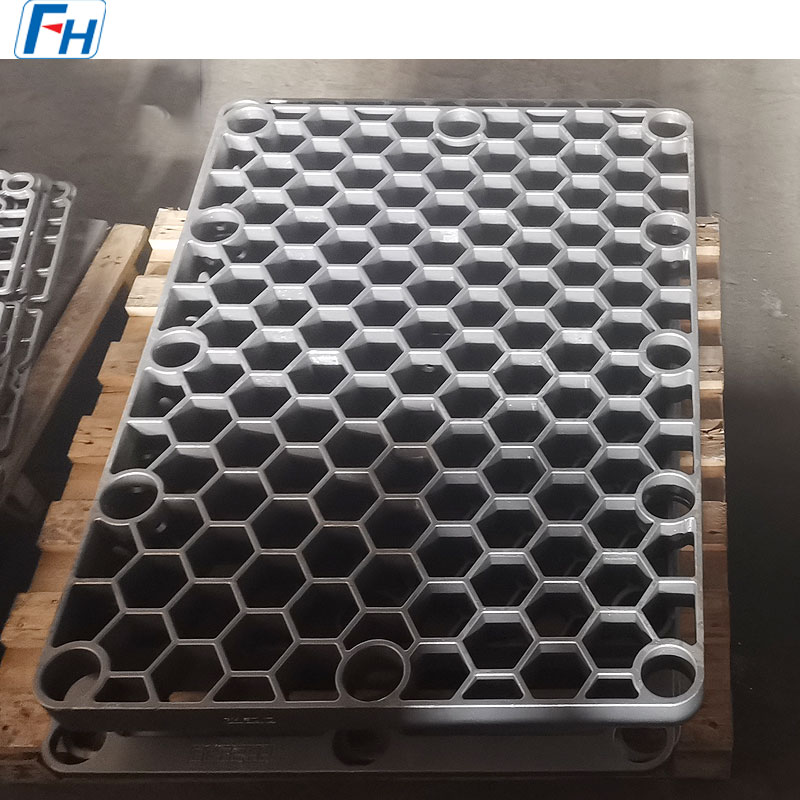

The chain plate is the core transmission component of a chain casting furnace. Typically made of 304/316 stainless steel or galvanized steel, it features high load-bearing capacity, high temperature resistance, and corrosion resistance. It forms a closed-loop conveyor track within the furnace, driving the continuous, uniform, and controllable movement of workpieces or billets during heating, pouring, and cooling processes, thereby ensuring stable process parameters and product quality.

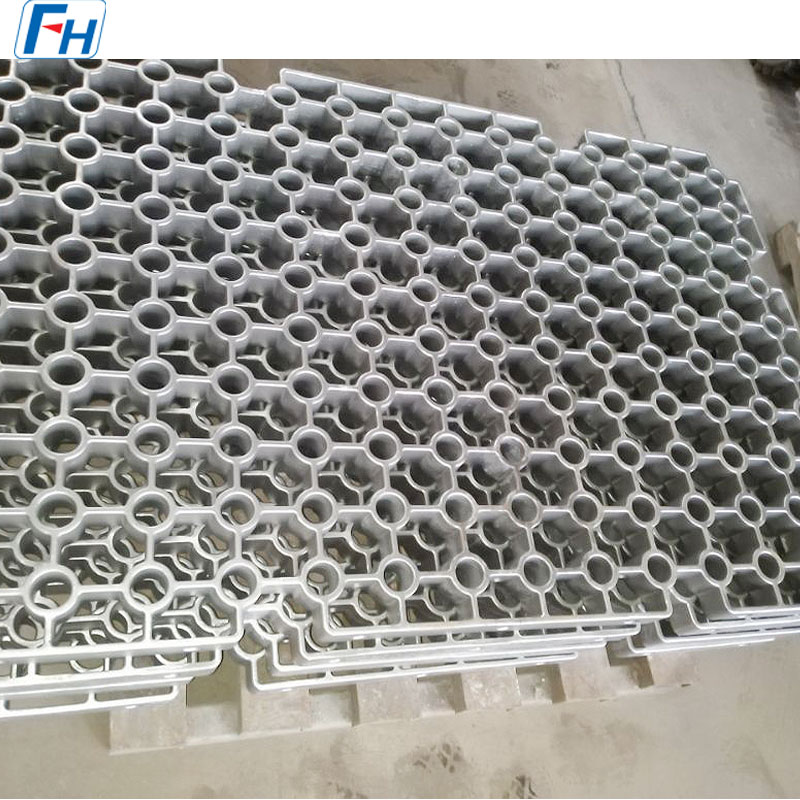

1. Structure and Material: The chain plate consists of several links and a support plate. The links are made of high-strength alloy steel with a heat-treated or stainless-steel surface treatment to withstand operating temperatures of 200-1050°C.

2. Function: It provides a reliable conveying path, ensuring smooth pouring or circulation of molten metal or heat-treated workpieces within the furnace, reducing the risk of manual operation.

3. Application: It is widely used in chain furnaces in industries such as metal smelting, heat treatment, drying, and baking, such as glass packaging furnaces, metal packaging furnaces, and food drying tunnel furnaces.

4. Maintenance Advantages: The modular design facilitates quick chain link replacement, reducing downtime and improving overall equipment availability.

What are the advantages of Wuxi Junteng Fanghu's lost-wax precision casting and centrifugal casting processes?

Since 2006, Wuxi Junteng Fanghu Alloy Casting Co., Ltd. has specialized in these two core processes, precision casting and centrifugal casting, establishing a comprehensive technical system and service network.

1. Lost-wax precision casting (investment casting): Using high-precision wax patterns and refractory materials, it is possible to create alloy parts with complex shapes, fine wall thicknesses (≤0.5mm), and high dimensional accuracy (±0.02mm). The process strictly controls the pouring temperature and cooling rate, significantly improving the density and mechanical properties of the castings.

2. Centrifugal Casting: This process utilizes high-speed centrifugal force to evenly push molten metal toward the mold walls. It is suitable for producing large pipes and radiant tubes with diameters ranging from 50mm to 1000mm and lengths exceeding 5.5m. This process achieves extremely low porosity and excellent wall thickness uniformity, making it particularly suitable for high-temperature resistant components such as furnace rollers and heating tubes.

3. Technical Advantages: Both processes are equipped with automated pouring systems, intelligent temperature control platforms, and online quality monitoring, enabling mass production with low costs and low waste. The company holds numerous patents and experience in process improvement, enabling precise adjustment of process parameters based on customer needs.

4. Service Value: We provide one-stop technical support from mold design, process simulation, and finished product testing, helping customers shorten R&D cycles, reduce testing costs, and improve the overall efficiency of their heat treatment equipment.

What types of melting furnaces are the chain plates provided by Wuxi Junteng Fanghu Alloy Casting Co., Ltd. compatible with?

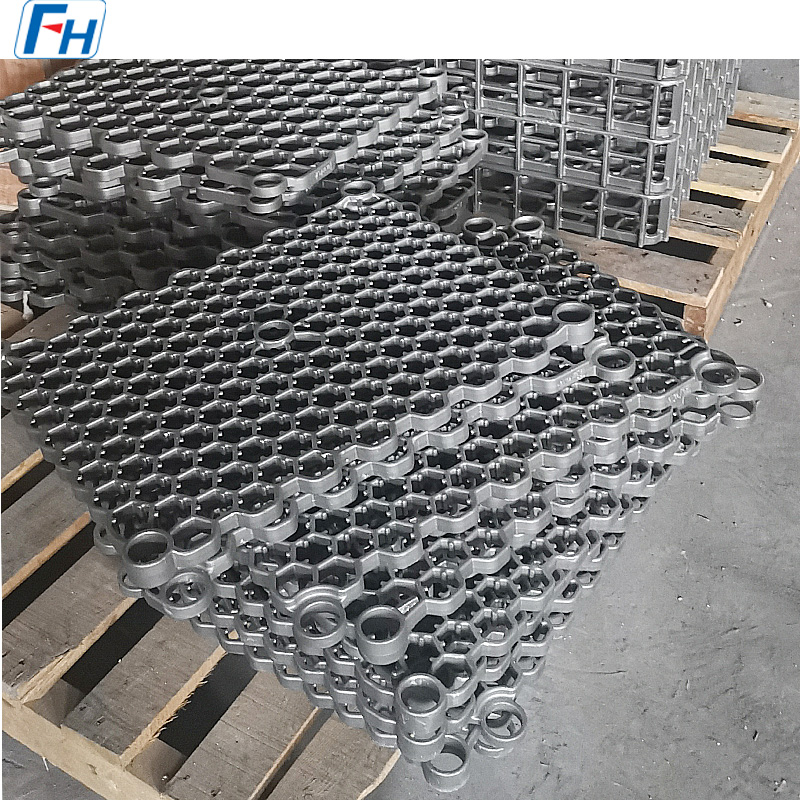

Leveraging years of experience in supporting chain furnaces, the company has provided standardized and customized chain plate products to many well-known domestic and international heat treatment equipment manufacturers.

1. Well-known Domestic Manufacturers: Numerous furnace manufacturers in Fengdong, North China, and East China regions have selected our chain plates as core transmission components.

2. Model Coverage: From small laboratory chain furnaces (power ≤5kW) to large industrial chain melting furnaces (power ≥200kW), chain plates can be customized in size, hole spacing, and material based on furnace width, conveyor speed, and operating temperature.

3. Compatibility: Our chain plates feature a modular structure with standard interfaces compatible with major chain furnace brands. We also provide on-site commissioning and technical training to ensure fast assembly, smooth operation, and maximize the lifespan of our customers' equipment.

English

English Español

Español italiano

italiano Deutsch

Deutsch 0086-13338774804

0086-13338774804

Tel: 0086-510-88331288

Tel: 0086-510-88331288  E-mail:

E-mail:  Add: No.26 Baoyuan road, Section B Yangjian Industrial Park, Wuxi, Jiangsu, P.R. China P.C.:214107.

Add: No.26 Baoyuan road, Section B Yangjian Industrial Park, Wuxi, Jiangsu, P.R. China P.C.:214107.