0086-13338774804

0086-13338774804

Get in Touch

Feb 09, 2026

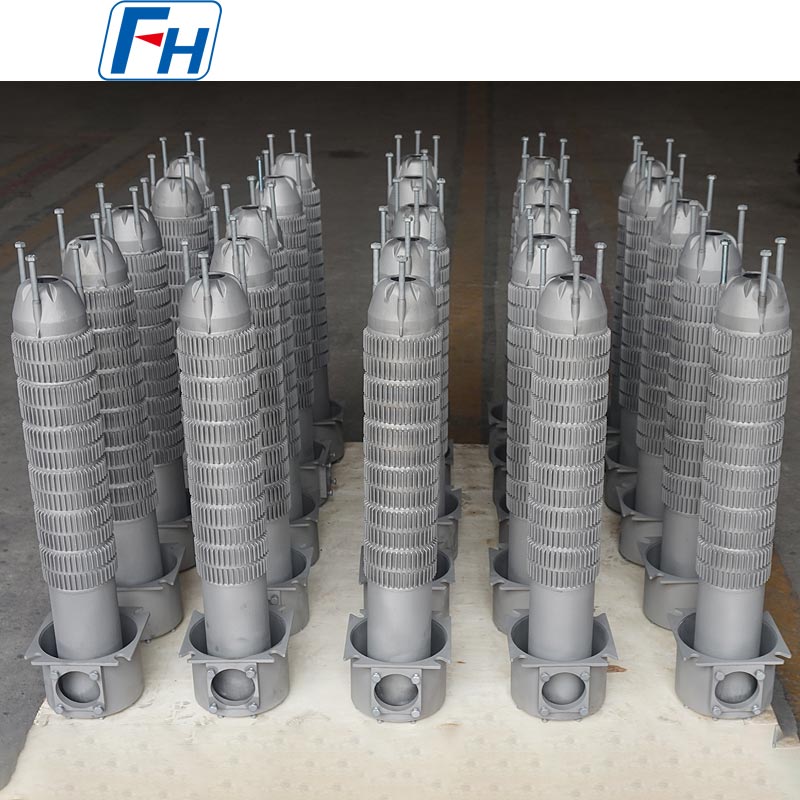

Feb 09, 2026 FH® (Wuxi Junteng Fanghu Alloy Technology Co., Ltd.) is a professional manufacturer of Preheaters.

In the world of metalworking, achieving precise and efficient heat treatment is essential to ensuring the quality and durability of metal components. Whether you’re working with steel, aluminum, or other metals, the process of preheating is crucial in maintaining the integrity of the material before further treatments like forging, welding, or casting. That’s where FH® Preheaters come in—offering high-performance heating solutions that are designed to meet the demands of modern metalworking industries.

What Makes FH® Preheaters the Best Choice for Metalworking?

1.Superior Heat Efficiency

One of the main advantages of FH® Preheaters is their high thermal efficiency. These preheaters are designed to maximize energy use, ensuring that your metal components are heated quickly and uniformly, which reduces energy costs while improving overall processing speed. Whether you’re heating metal for forging, casting, or heat treatment, the efficiency of FH® Preheaters ensures consistent results every time.

2.Reliable Heat Resistance

Metalworking often involves working with high temperatures, and it’s essential that the equipment used in the process can withstand extreme conditions. FH® Preheaters are built with advanced heat-resistant alloys that can handle temperatures upwards of 1000°C (1832°F), making them ideal for the high-heat demands of metal processing. This durability ensures that your equipment will last longer, reducing downtime and maintenance costs.

3.Precise Temperature Control

Achieving the right temperature is critical in metalworking. Too much heat can cause the metal to become brittle, while too little heat can prevent proper bonding or fusion. FH® Preheaters offer precise temperature control, ensuring that your metal components are heated to the ideal temperature for the specific process. This precision helps to improve the quality and consistency of your finished products.

4.Versatility Across Applications

Whether you're working with steel, aluminum, copper, or other alloys, FH® Preheaters are versatile enough to handle a wide range of metals used in various applications. From metal forging to casting, welding, and even heat treatment, FH® Preheaters are perfect for industrial metalworking processes. Their flexible design means that they can be customized to suit different production lines, ensuring compatibility with your specific setup.

5. Energy Efficiency & Cost Savings

As energy costs continue to rise, it’s crucial to adopt equipment that helps you reduce consumption. FH® Preheaters are engineered with energy-efficient features to optimize heat distribution, ensuring less heat loss and more efficient energy use. This translates into cost savings for your business over time, making FH® Preheaters not just a smart choice for performance, but also for your bottom line.

Applications in Metalworking

FH® Preheaters are used across various industries for a wide range of metalworking applications. Some common uses include:

Why FH® Preheaters Are the Future of Metalworking

The metalworking industry is constantly evolving, and as it does, the need for more efficient, reliable, and cost-effective solutions grows. FH® Preheaters are designed with this future in mind, offering innovative solutions that help manufacturers meet the demands of a changing market. Whether you're in aerospace, automotive, heavy machinery, or other industries that rely on metalworking, FH® Preheaters provide the performance and durability that modern manufacturers need to stay ahead.

Conclusion

If you're in the metalworking industry and looking to optimize your heating processes, FH® Preheaters are the solution you need. With superior heat efficiency, reliable heat resistance, precise temperature control, and versatility across various applications, FH® Preheaters help improve product quality, reduce energy consumption, and save costs over time.

Explore the full range of FH® Preheating Solutions and take your metalworking processes to the next level!